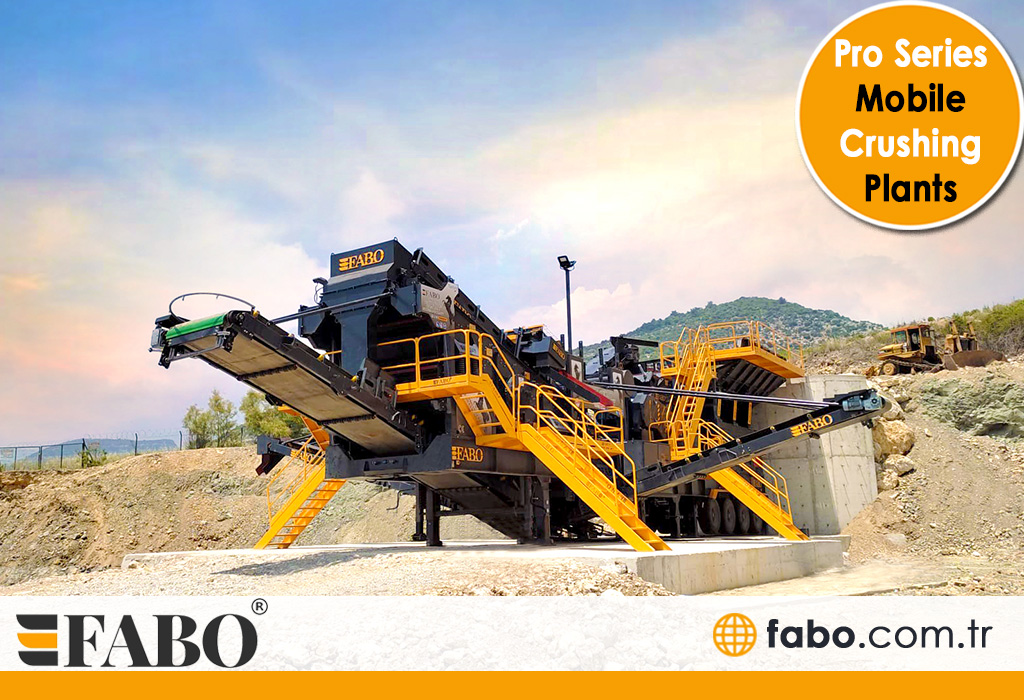

Mobile crusher has revolutionized the construction industry by providing a versatile and efficient solution for on-site material processing. These machines reduce transportation costs and environmental impact by eliminating the need to transport large quantities of material to off-site processing facilities. Thanks to their compact design and mobility, mobile crushers can be easily moved to different locations. This makes them ideal for projects that require frequent relocation.

Mobile crusher plants are equipped with advanced features such as automatic controls, robust engines and efficient crushing mechanisms. These features keep the machines running at high performance, ensuring consistent, high-quality raw materials. Integrating screening plants and impact crushers into mobile units ensures a comprehensive and efficient crushing process. This not only increases productivity, but also improves safety on construction sites by reducing the need for manual handling of materials.