It is in a very good position in the world in the field of ” Turkey mobile crusher ” production. All types of crushers are produced in the country and exported to the whole world. Even the world’s largest mobile stone crushing plant ” production was carried out by Fabo in Turkey . The product has the model name Pro-150.

“ Turkey mobile crusher ” stands out with its rich model variety in the field of solutions. Although the manufacturer has several company options, Fabo is at the forefront with its machines that offer high performance and long service life. The machines are produced as a result of the devoted work of experienced engineer staff and technicians. A “ stone crusher ” plant ” basically consists of crusher machines.

“ Turkey Mobile Crusher Production ”

“ Stone crushers ” together with optional components such as vibrating screens and cement silos constitute a crushing and screening plant. In these facilities, stones or rocks are broken into smaller pieces. The material obtained after the crushing process is separated by means of sieves. Thus, materials with similar dimensions are grouped.

Stone crushers are also called crushers. The stone material that is broken down by crushers is called “ aggregate ”. Aggregate is a mixture of sand and gravel that forms the raw materials of concrete. Concrete can be produced with this mixture. Crushers can be divided into mobile crushers and fixed crushers according to their portability.

Mobile crushers can be easily transported with the help of a truck. It occupies less space and is suitable for projects to be continued in different regions. But production volumes are lower than stationary crushers. It is frequently preferred in short-term projects. Fixed crushers, on the other hand, are machines with extremely high crushing performance. It is suitable for projects that are planned to be continued in the same region. A stationary crushing and screening plant can also be transported. However, this is more difficult and costly.

“Mobile Crusher Turkey ”

“ Turkey mobile crusher ” is a country where production is common. Developed by Fabo , the world’s largest mobile crusher . Its performance is also extremely high in direct proportion. The mentioned machine has the model name Pro-150. It has a production capacity of 250-350 tons.

Crushers;

- Build

- Mining

- Recycle

- Landscape

It is used in many sectors that can be listed as. Municipalities also benefit from these machines.

Tracked mobile crushers take mobility one step further. Thanks to the pallet, these machines can have high mobility in the working area. Their production capacity is also quite high. They can travel a distance of 1 km per hour. High mobility crushers reduce the assembly and disassembly costs of companies and reduce transportation costs. It can be used for many years. It can do all the work that stationary breakers can do.

One of the areas where mobile crushers are used most frequently is mobile project areas. Crushing and screening plants are usually installed on the site of the raw material intended to be processed. For this reason, they work in difficult areas such as stream beds and mineral deposits.

“Mobile Crushers ”

Firms generally see crusher plants as a long-term investment tool. Therefore, when the existing project is finished, they may want to assign the crushers to a different project. At this stage, the transportation and assembly of the plant can be challenging. However, a mobile facility greatly reduces the hassle and expense of moving.

Not every machine shrinks stones or rocks to the same extent. Because each business can perform the breaking process for a different purpose. Crushers can be examined in 3 groups according to their material reduction ratio.

- Primary (primary) breakers: These are the first stage breakers. They are generally involved in the breaking of medium-hard materials. The reduction level is not high. The stones are roughly broken.

- Secondary (secondary) crushers: They provide crushing of materials with medium or high hardness value. They can bring the materials to the desired fineness level within certain measures.

- Tertiary (tertiary) crushers: They can reduce materials until they reach the size of sand.

“ Crusher Types ”

Regardless of whether the crushers are fixed or mobile, they can be divided into three according to their working principles.

- “ Jaw crusher machine ”: Mobile “ jaw “ Crushers ” carries out the crushing action with the effect of high pressure applied during this time. Thus, even large and hard materials can be broken. Materials trapped between jaw-like plates, one of which is fixed and the other is movable, break.

- “ Cone crusher ”: It can be used to obtain materials both large and as small as sand. It can break stones and ores of all hardness levels. It reduces materials by breaking them with the help of compression or shear forces.

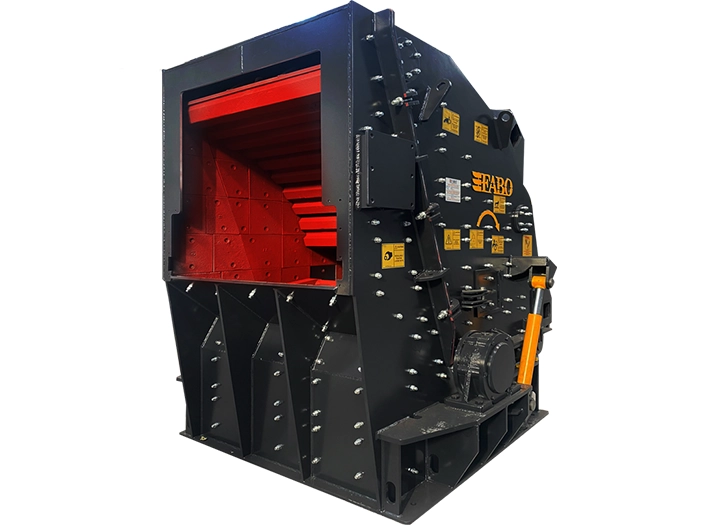

- “ Impact crusher ”: They are machines produced for crushing medium and low hardness materials. It causes two stones to collide with each other, causing them to break. Afterwards, the movement of the impact plates on both the upper and lower wings makes these parts even smaller.

Each crusher type has sub-models equipped with different technical features. You can make a good start by choosing the most suitable one for your project among the rich product/model variety. If you are not sure which machine or facility to choose, you can get help from our experts.