Jaw crusher is one of the most important equipment of the concaveplants. It can be designed in two different ways, mobile and stationary. This type of crusher breaks large stones in crushing and screening plants, bringing them to smaller sizes. Thus, aggregate is obtained from stones.

Jaw crusher are very powerful crushers that can be used in premier (primary) and secondary (secondary) crushing processes in crushing and screening plants. It can easily shrink hard and a corrosive stones such as marble, granite, basalt to desired sizes.

What is Jaw Crusher?

Concave plants are large plants that break down large-sized stones and turn them into smaller-sized materials. Stones that are made small and cubic are used in the construction sector. Aggregate, which is usually needed for ready-made concrete production and road construction, can only be produced through concave plants. Therefore, the basic material for many sectors is produced in concave plants. Concave plants consist of many different equipments.

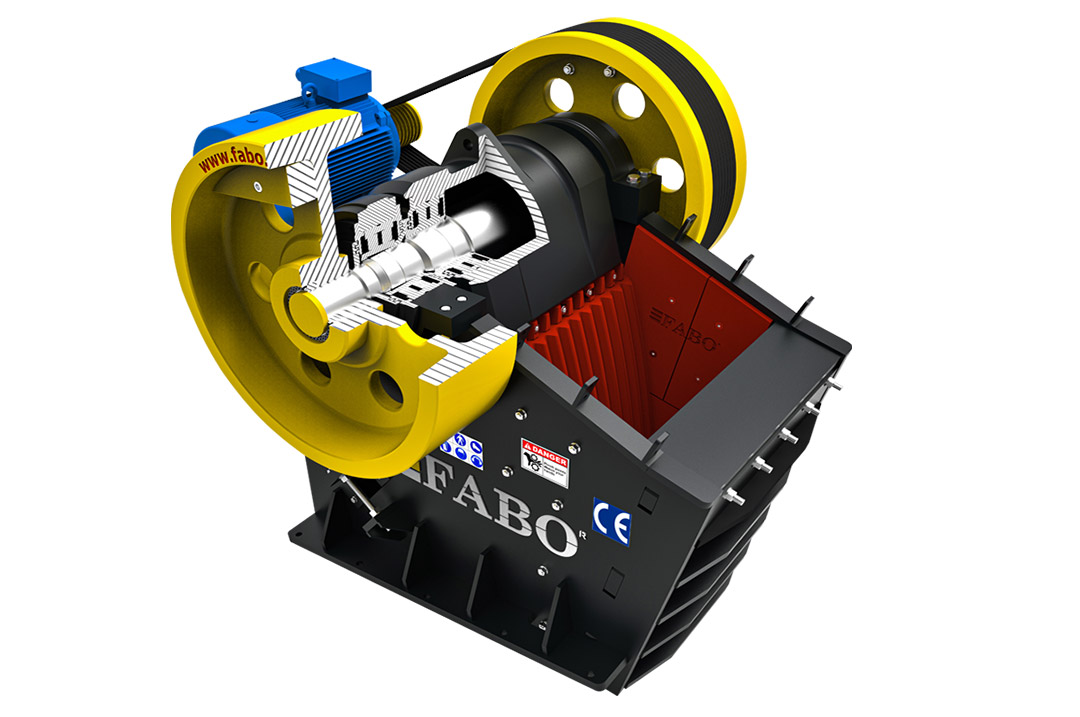

In concave plants, the crushing process of stones occurs in machines called crushers. Crushers break down untreated large stones, bringing them to small sizes. Today, different types of crushers have been developed. This is because stones of different hardness and properties can only be broken with different systems. Jaw crushers are one of these types of crushers. Jaw crushers break stones through two moving jaw plates, one fixed and one moving. Jaw crushers are mostly used to break stones with high hardness. Jaw crushers, which can easily break down hard stones such as granite and basalt, can also be used to break down mines of less hardness.

Jaw Crusher Working Principle

Jaw crushers are a type of crusher with a unique system. Jaw crusher, which is a very strong type of crusher, performs the crushing process with the help of two plates. One of these plates works by making constant, the other by making elliptical movements. The stones are shattered by the pressure exerted by these two jaws. The principle of jaw crusher operation is as follows;

- Compresses jaw-dropping stones between two moving jaws, one stationary and one moving

- Applies a high amount of pressure to the stones during this compression

- Stones exposed to high pressure and force crumble

- Pieces of stone to desired dimensions are sent to the lower chamber

Jaw crushers are generally preferred as primary crushers in crushing screening plants. This is due to the fact that jaw crushers cannot bring the stones to the dimensions to be processed directly. Stones processed in jawed creases are usually subjected to a secondary crushing process.

How Does Jaw Crusher Work?

Concave plants are the facilities that produce small pieces of stone, called aggregates, which are needed by the building industry. Aggregate is often used as the main material for making ready-made concrete. In addition, it is used as a sub-material inroads and some large structures. The aggregate used in each area must be of different sizes and characteristics. The size of the aggregate produced depends on the way it is processed and the crusher. Aggregate produced in jaw crushers is usually not used as the final product. This is due to the material coming out of the jaw crusher not being sufficiently reduced. Because hard stones are processed in jaw crushers. High hardness stones cannot become the final material by going through a single crushing process. A secondary crushing process is needed.

Jaw crushers perform primary crushing in the concave plants. The jaw crusher consists of two jaws. One of them is fixed, the other is mobile. Stones sent to the jawed whip chamber are trapped between the moving jaw and the fixed jaw. The moving jaw, which has a continuous elliptical movement, uses pressure to crush and break down stones.

Jaw Crusher Equipment

Jaw crushers are designed to break down the hardest stones and mines. It can easily break down hard stones and mines such as granite, basalt, stream bed material. The jaw-dropping crusher, which takes the material to be processed to its fixed and moving jaw, compresses and breaks with elliptical movements, bringing it to smaller dimensions. Jaw crushers produce with the synchronized operation of different equipment. Jaw crusher equipment is as follows;

- Jaws: Consists of two parts, fixed and moving. Since the breakdown of materials occurs in this part, the most wear occurs in these parts. Therefore, it is manufactured as cast of manganese steel and can be used on one side and the other side when it is vaccinated.

- Bearing Plate: The drive system has two tasks to ensure safety and security and to provide extra breaking force to the jaws. When the eccentric shaft rotates; safety plate allows the pitman and moving jaw to break downwards.

- Side Lining Plates: Side linings keep the fixed jaw where it should be and form the crusher room. It is obtained from abrasion-resistant manganese steel casting. The plates attached to the body with screws can be easily replaced in case of wear.

- Crusher Body: Made of low carbon steel to minimize pressure on the crusher.

- Shaft and Bearings: The shaft allows the material to move under the jaw. It is produced from heat treated steel. Bearings, on the other hand, provide optimal power to the pitman shaft, extending the maintenance time of the machine.

Jaw Crusher Types

Concave plants used to be produced in only one type and several models. However, today, concave facilities are designed in different structures. These are the ones that are going to fixed concave plants and mobile concave plants. Fixed concave plants are built on a fixed body. Fixed concave plants are installed in the work area and have a high production capacity. Mobile concave plants have a portable body. Mobile concaves with their own motion system can be easily transported to another area with the help of a tow truck.

With the development of mobile concave, mobile concave equipment was also started to be designed. Mobile jaw crushers are also a type of jaw crusher with a portablebody. Mobile jaw crushers can be easily transported from one workspace to another.

Another type of jaw crusher is fixed jaw crushers. Fixed jaw crushers are crushers fixed to the work site. It has a higher production capacity than mobile jaw crushers. Both types of jaw crushers have their own advantages.

Mobile Jaw Crusher

Mobile jaw crushers are jaw crusher models built on a single chassis. This chassis has its own wheel system. With the help of a tow truck, it can also be easily transplanted to another area. Mobile jaw crushers offer significant advantages to user companies. The advantages of mobile jaw crusher are as follows;

- They have flexible working ability: theycan be optimized to adapt to different application areas.

- Increase profitability by using it for a long time: They have the same length of life as fixed crushing plants. They are offered for sale after long R&D studies and quality control tests.

- They save energy and do not harm the environment: theyconsume less energy thanks to the specially developed engine structure. Damage to the environment with de-pollination systems is minimized. In addition, reducing logistics costs also reduces carbon emissions.

- They can be used by a single operator: theycan be easily managed by a person thanks to the automation system equipped with advanced technology.

- Easy tomaintain: They can be maintained in a short time with a large service heavy and can return to operation.

Fixed Jaw Crusher

Fixed jaw crushers are crusher models fixed to the work area. Unlike the mobile jawcrusher, it is not easy to transport. Fixed jaw crushers installed in the work area stand out with their high production capacities. The advantages of fixed jaw crusher are;

- High production capacity: Fixed jaw crushers can be between 60 and 600 tons of stone crushing capacity per hour.

- It can be used smoothly for many years: fixed-jaw crushers are designed to process hard stones. Therefore, it is produced using extremely robust and long-lasting materials.

- Works with automation system: Fixed jaw crushers have advanced automation system. In this way, it can perform many operations automatically.

- It can be used in different crushing processes: Fixed jaw crushers can be used as primary crushers or secondary crushers in crushing and screening plants.

Primary Jaw Crusher and Secondary Jaw Crusher

These machines, which work as primary and secondary jaw crushers, can be easily supplied according to the needs of your business. When buying such machines, you need to take good care of the reliability, performance and durability characteristics. Jaw crusher prices vary according to the details that the needy pay attention to. The flywheel speed, jaw-catching angle and other materials that the machine has affect the price. These features also come to the forefront of security. Flywheel bellies cause large problems in large jaw crusher varieties. Therefore, flywheels should be used using special tightening systems.

Jaw crusher prices may also vary depending on the Primary or Secondary type. Jaw crusher machines can process very hard rock structure into the arm. Jaw crusher manufacturing facilities can prepare machines according to your needs. When installing these systems, assembly work is extremely important. Designed for heavy processing, these machines need to operate at maximum efficiency. It affects the production cost per tonne of part changes that will occur from wear. Therefore, jaw crusher prices increase in direct proportion to quality. You can reach the jaw-breaking machines that your business will need from our company at the most affordable prices. We help you to do business with maximum efficiency with our special systems. You can call us immediately for detailed information about jaw crushers.

FABO Global Jaw Crushers

FABO Global jaw crushers are designed to break down the hardest stones and mines. The plaques that make up the jaw part of the jawed breakers consist of MN alloy plates. In this way, the jaws can work smoothly for many years. The characteristics of FABO Jaw crushers are as follows;

- Belt – pulley drive system

- Mn plates made of special abrasion-resistant casting

- Eccentric shaft made of Cr, Ni, Mo alloy forged steel

- Hydraulic adjustable jaw openness

- Safety plates against excessive strain

- Abrasion-exposed surfaces are covered with primer plates

- Hhas idrolic adjustment mechanism

- The crusher shafts are made of 4140 forged steel and are bearing with spherical spherical roller bearings.

Jaw Crusher Prices

FABO Global concrete plant and concave plant productioniseitherp. In addition, it has been producing concave plant equipment for many years. FABO Global products are used safely in many parts of the world today. The machines produced by the company, which specializes in the field and has managed to become a global brand, are designed byits own engineers.

FABO Global designs all the concave plant and concave plant equipment needed by companies. In this context, many jaw-dropping crusher models can be offered to business partners. You can contact FABO Global for information about jaw breaker prices in different models.