The dewatering screen is the equipment of a stone crushing and screening plant used to obtain quality sand. A standard screen cleans organic materials on the sand with water so that aggregate become clean enough to be used in concrete production.

A dewatering screen is of critical importance for a crushing plan. After washing sand with water to clean, the sand becomes moist and unusable untill drying. Drying process takes a long time and increases inventory costs.

What is A Dewatering Screen?

Concrete — a requirement for the construction industry — is a component obtained by mixing certain proportions of sand, cement and water together. Sand is the basic material of cement production and produced in stone crushing and screening plants that is also called crushing plants. Sand is formed by crushing large-sized stones and must have some standards in order to be of sufficient quality for use in cement production.

In order to achieve these standards, sand must go through some stages. Apart from crushing into small pieces, sand should also be screened and cleaned. The dewatering screen is the equipment that increases the quality of the sand by drying it after washing.

Working Principle of Dewatering Screen

The main task of the dewatering screen is to clean and dry the washed sand in a short time. The principle of this process is as follows:

- The washed sand is first sent over the inclined polyurethane panels.

- The material is moved upwards by means of two vibromotors in the direction of 5 degrees inclination

- Water stays where it is while the material climbs up

- A pool is formed here.

- Thus, other organic components adhering to water and sand are thrown out of the screen.

- Water is sent to the system to be used again.

Thus, the sand passing through the screen becomes ready to use as dehydrated.

Where To Use Dewatering Screen?

The sand becomes very fine through the crusher used in the crushing plant. The washing and dewatering unit is a necessary equipment to clean the sand by sieving it from sulfur, clay and organic materials. Because the structure of the sand directly affects the quality of the concrete to be obtained. Therefore, dewatering screen is significant for sand required to produce good quality concrete.

Dewatering units are mostly used in following works:

- In projects where sand is produced for use in construction

- Sand production projects used in industrial areas

- Crushing plants producing sand for use in the building sector

- In facilities that want to produce high quality concrete sand

The screen has a very wide usage area. And its performance is critical in terms of the capacity of the facility.

Spesifications of Dewatering Screen

The sand subjected to washing process holds an average of 20% of water. The main feature of the dewatering units is to discharge the water from the sand by passing the sand through certain processes. It shortens the long period of removing the sand from the water and resolves the stock problem that may ocur in the production facility.

Other features of the dewatering unit, which is an important part of the screening and washing system, are as follows:

– It discharges the water absorbed by the sand in a short time.

– It provides sand to be purified from organic materials

– It increases the purity of the sand

– It assist to obtain better quality concrete

– It decreases the stock cost of the firm

FABO Dewatering Screen

Since the day it was founded, FABO has been working to produce the highest quality stone crushing and screening plants and concrete plants in the industry. In addition to the production and supply of crushing plants and concrete plants, FABO Global also manufactures equipment that enables these facilities to operate more efficiently, and also manufactures the highest quality and robust dewatering screens on the market.

FABO always promises the best to its business partners by producing crushing plant and additional equipment with its expert and extensive engineer staff in the field. It is also very assertive about vibrating screen and dewatering screening systems. Fabo dewatering machines are powerful machines with a long service life.

Advantages of FABO Dewatering Screens

The most important point in dewatering systems and crushing plants is the company manufacturing or supplying the machines. These large companies have very high costs and require many spesifications to perform well such as production of quality products by experts. In this context, the advantages of FABO dewatering screens for user companies are as follows:

– It is produced within the latest technologies

– Cleaning the sand from both water and dirt.

– High performance and compatibility with the crushing plants

– Maintenance can be done easily and comfortably

– Simple transportation and assembly processes

– It has FABO guarantee and assurance

Things to Consider When Buying a Dewatering Screen

Buying a dewatering screen is as important as purchasing other crushing plant products. Because, crushing plants do not consist of a single machine, but are designed in a structure where many different machines and equipment work in harmony. The harmony they create with each other is as important as the performance of these equipment alone.

The most important point to consider when purchasing a dewatering screen is the capacity, efficiency, durability and high performance of the screen for many years. This can only be done by purchasing from a reliable company. Therefore, the purchase must be made after supplying company’s products and works carried out are examined carefully.

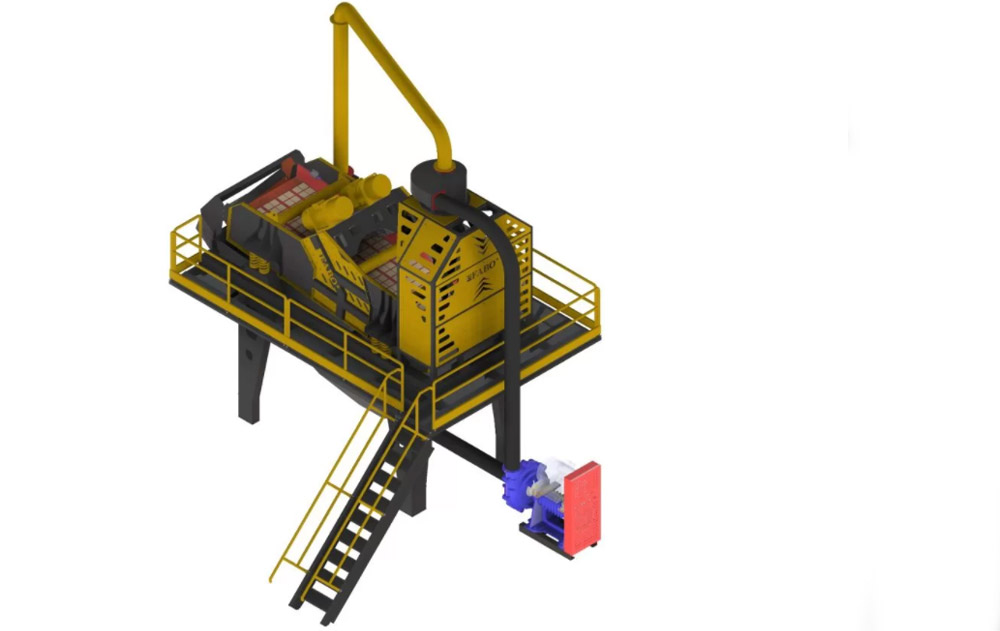

Stationary Dewatering Plant

Stationary dewatering plant is a facility designed on a single fixed body. It purifies sand from water after washing. FABO stationary dewatering plant has the potential to produce an average of 80 to 120 tons per hour. The dewatering unit with 5.6 square meters of screening surface has an 8 degree inclination.

The facility has a total weight of 7500 kg. It can be easily transported and installed. (You can click here to view our product in more detail.)

Dewatering Screen Prices

There are different models and types of dewatering units in the market. Before the sieve is purchased, the properties of the product to be washed should be determined thoroughly. And a dewatering unit suitable for these features should be purchased.

As FABO Global, we provide all necessary information and guidance to companies that we supply machines before purchasing. You can contact us for dewatering sieve prices and more detailed information.