Stone Crushing Machine

Stone crushing machine is also known as crusher plant. These plants are divided into two main groups as mobile crusher plant and fixed crusher plant. The facilities are powerful crushing and screening centers that break large stones into small ones.

Stone crushing machine do? The stones crushed by these machines are used in the production of ready-mixed concrete. In order to obtain ready-mixed concrete, a high amount of small, cubic stone pieces called aggregates are required. These small-sized stones are also produced in crusher plants.

What is Stone Crushing Machine?

From past to present, people have built different structures for different purposes. Different types of materials were used in these structures. But as a result of today’s trials, building materials with the best performance are used all over the world. At the beginning of these materials are basic materials such as iron, concrete and brick. In particular, concrete is used at almost every stage of construction. Thanks to its strong structure, it extends and strengthens the service life of buildings.

Ready mixed concrete used in the construction industry is transported to the project area by concrete mixers and conveyed to the relevant areas. Ready mixed concrete consists of cement, aggregate and water. At this stage, the most needed raw material is aggregate.

What is aggregate? It is the processed small sized stone pieces required for the production of ready-mixed concrete. Aggregate production is carried out through crusher plants. Large stones or mines sent to the crusher plant go through some processes here. First of all, it is subjected to shredding by means of crushers. It is then classified into appropriate sizes. Thus, aggregates of different sizes are obtained for different areas needed.

How Does a Stone Crushing Plant Work?

crushing and screening plant , also known as the crusher plant, consists of machines designed for the processing of stones and mines. Crusher plants reduce the stones extracted from the stream bed or mineral deposits to small sizes. These shredded materials are used in different areas in the construction industry. The most used areas of aggregate are as follows;

- In the production of ready-mixed concrete in the construction/building industry

- As a sub-material in road and asphalt works

- As a building and filling material in airport projects

- dam construction

- In transportation projects such as tunnels and bridges

So how do stone crushing and screening plants work? Crusher plants consist of many equipments with different tasks. Untreated coarse stones and minerals are first conveyed to the crushers. Here, the disintegrated mines are sent to the sieves. The stones that become aggregates are classified according to their size in the sieve. Thus, the aggregate becomes ready for use.

Mobile Stone Crushing Plant

Mobile stone crushing plant is a crusher plant built on a portable body. Unlike the stationary crusher plant, the mobile crusher plant can be easily transported from one area to another. It has a lower production capacity compared to the fixed crusher plant. However, its usage area and capacity are gradually increasing. It is effective in this that companies reduce some of their expenses. Transportation, assembly and disassembly costs are among them.

Since mobile crushers are easy to install or transport to the project area, the working area is quite wide. Mobile crushers are often preferred in constructions, infrastructure projects and highway construction . In such mobile projects, the working area can change constantly. Since the plant has to be moved to other regions, the efficiency obtained from mobile crushers is higher. Since the fixed crusher plants are fixed to the project area, it is difficult and costly to relocate these plants.

The types of crusher machines used in mobile and stationary stone crushing plants can basically be limited as follows:

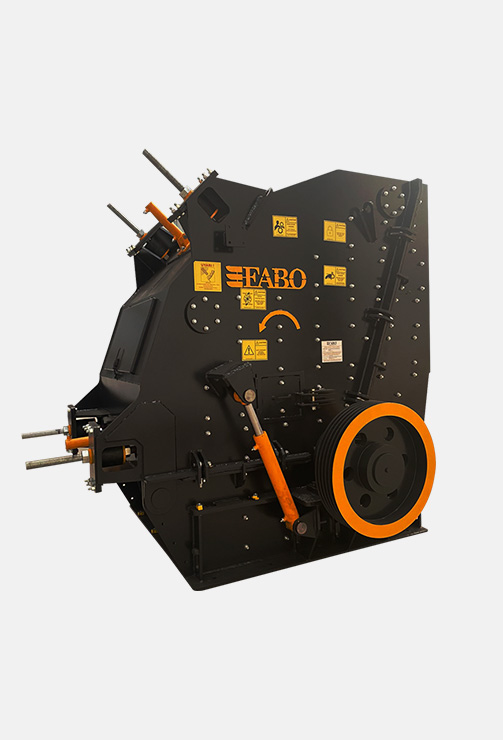

- jaw crusher

- cone crusher

- impact crusher

There are also different subtypes of these machines. For example, the vertical shaft crusher produced by FABO is a type of impact crusher.

Fixed Stone Crushing Plant

Fixed crusher plants are the type of crusher plant that is generally preferred in long-term projects. They are stone crushing and screening facilities used to bring large-sized stones to smaller sizes. The most important advantage of fixed crusher plants is that they produce at high capacity and with these features they reduce the production costs of the companies.

It provides advantages to companies in projects where the project site is in the same place throughout the entire project. Companies that need high-capacity aggregate production have higher efficiency from this type of facility. Fixed crusher plant is built in the project area. Therefore, it can operate at higher capacities. The amount of aggregate produced per hour is higher than mobile crushers. Thus, it can produce high quantities in a short time.

So how is a stone crusher made ? These machines work like a semi-robot, move according to the directions of the user and perform the stone crushing process. Employees from different fields are involved in the manufacturing phase of the machines. As a result of the harmonious work of mechanical engineers, industrial engineers, software engineers, technicians and qualified workers, the machines are ready.

Each production detail is well planned and made with the guidance of the relevant officer. Designing and assembling parts is also a job that requires experience . FABO continues to increase its machine production with years of experience in its field.

Fixed crusher plants can operate without any problems for many years after they are procured and installed once. It can be considered as a long-term production facility if necessary maintenance is done. You can contact FABO Global for detailed information about the crusher plants you need .

Stone Crushing Machine Prices

The price of stone crushing machine is a subject that both entrepreneurs and companies operating in this field frequently research and want to have information about. Conditions such as exchange rates, type and purpose of use of the machine, technical specifications of the machine, whether to purchase an additional service, “ How much is the price of the stone crusher machine? It also affects the answer to the question.

Due to the reasons listed, prices can be updated frequently. Stone crushing plants are formed with crushing machines. Aggregate material required for concrete production is also produced by the machines in these facilities.

You can contact us by using our contact information on our website for price and detailed technical information about stone crushing machines with the features and types you need.