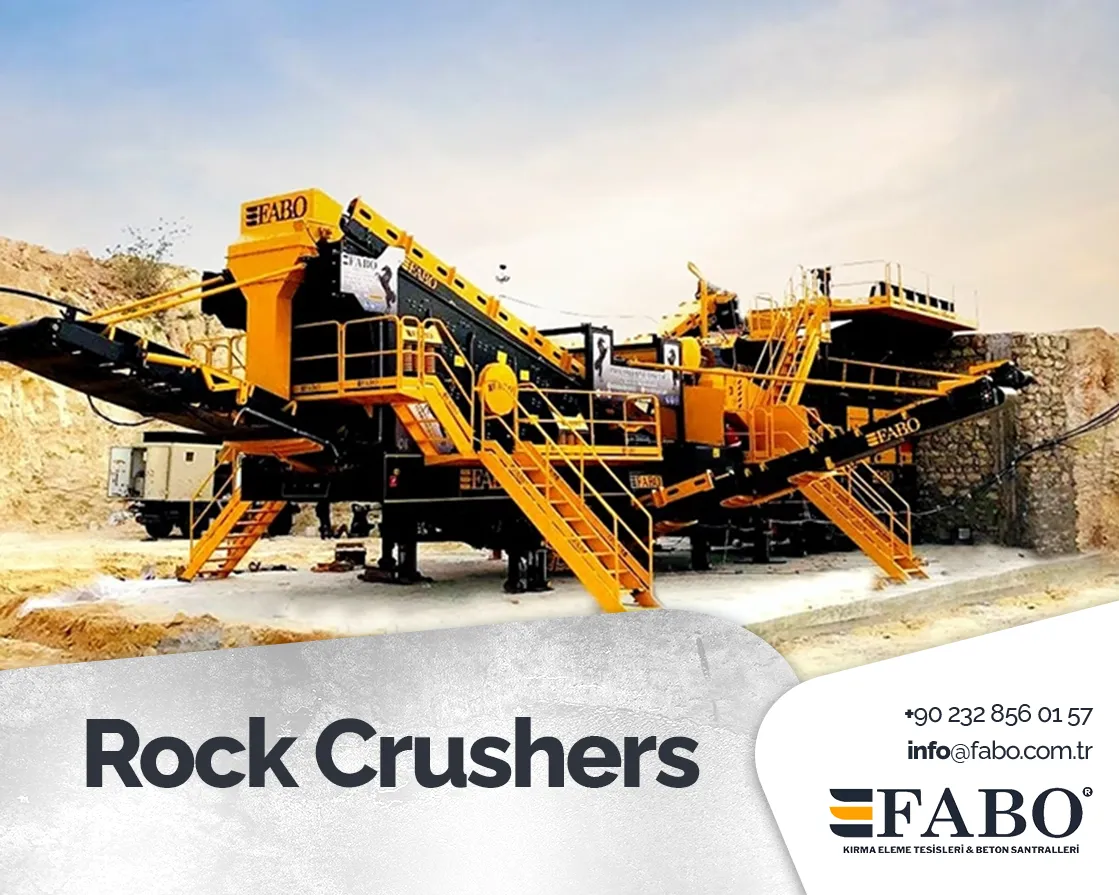

Rock Crushers

“Rock crushers” are high-performance machines with automation systems that can crush and break stones and rocks. Thanks to these devices, work can be completed with minimum manpower. These machines, also known as crushers, are frequently used in sectors such as building, construction and recycling.

Is there a “rock crushers” for rent option? For the machines used in the stone crushing and screening process, there is also the option of renting as well as purchasing as zero or second hand. However, since rental devices will have been used before, full efficiency may not be obtained. Zero products are guaranteed machines that operate at an extremely high performance. All kinds of technical support and spare parts services are offered for these machines.

Rock Crushing Machines

What is a rock crusher used for? These machines, also called crushers, are extremely functional, especially in quarries, mines or construction sites. Crushing plants are used to crush, reduce or screen stones or rocks of different sizes. The most important component of a plant is the crusher machine.

After the crushing process is carried out, it is necessary to screen the materials of similar size in order to group them. FABO, the leading company in the sector, is a company that stands out with its state-of-the-art machines and screens. Options such as vibrating screen or palletized scalper screen meet many needs of customers.

What machine crushes rocks? Crushers are built for this process. Crushing equipment is largely built with automation systems. In this way, the need for human labor has decreased and work has accelerated. You can contact us to access innovative technologies at affordable prices and talk about your projects.

Portable Rock Crushers

How many types of crushers are there? Crushers or crushers are manufactured in several different product groups and with a large number of model options. In addition to portable crusher options, there are also stationary crushers. Mobile or portable crushers can be easily transported from one project site to another with the help of a truck.

Stationary crushing plants are also portable to some extent. However, the transportation process is much more difficult and laborious. On the other hand, stationary crushers operate at extremely high performance values. As can be seen, crushers are divided into two according to their portability. “Crusher types” are divided into three according to their working principles.

This “machine” performs the crushing process with its jaw-like structure. One of the jaws is movable and the other consists of a fixed plate.

Generally preferred for crushing hard and abrasive rocks.

The material to be crushed is crushed by impact instead of pressure.

- Jaw Crushers

-

This “machine” performs the crushing process with its jaw-like structure. One of the jaws is movable and the other consists of a fixed plate.

- Cone Crushers

-

Generally preferred for crushing hard and abrasive rocks.

- Impact Crushers

-

The material to be crushed is crushed by impact instead of pressure.

Used Rock Crushers for Sale

“Stone crushers” consist of parts that wear out as they are used. For this reason, the life of used options is somewhat shortened. Brand new stone crushers are also guaranteed and offer a very long service life. The failed component is replaced or repaired.

Rock crusher products are the fixture of a crushing and screening plant. Screening is used to separate the crushed materials into similarly sized pieces. For example, a vibrating screen is used to sort the reduced stone or rock pieces into layers. Thus, the work is carried out in a more practical way.

Crushing machines are frequently used in construction sites, recycling plants or mines. Crushers or plants from FABO include all the basic equipment you might need in a plant. Auxiliary and optional products such as vibrating screens and cement silos support your work and increase your efficiency.