| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR |

|---|---|---|---|

| PRODUCTION CAPACITY | 180-250 HOUR | VIBRATING SCREEN SIZE | 2000x5000 mm |

| MAXIMUM FEEDING | 700 mm | TOTAL MOTOR POWER | 360 kW |

| IMPACT CRUSHER ROTOR | Ø 1200x1200 mm | GENERATOR – OPTIONAL | 630 kvA |

Vibrating Feeder Bunker

FABO Vibrating Feeder Bunkers have been developed by our engineers in a user-oriented manner so that the crusher on which it is positioned can operate with high efficiency.

The working intensity of the feeding bunker and primary impact crusher is coupled with the automation system.

This feature works in two steps.

1st step: If the density of the crushed product in the crusher is high, the amperage of the crusher increases, this rise is detected by the automation system and the vibration of the bunker decreases, preventing the product from accumulating in the crusher feeding chute. This feature prevents wear of the crusher.

Step 2: If the density of the crushed product in the crusher is low, the amperage of the crusher decreases. This decrease is detected by the automation system and bunker vibration increases. The feeding bunker starts to deliver the products to the primary impact crusher faster. This feature keeps the production capacity at the maximum level.

A1 quality springs, which provide the vibration of the bunker, have been specially designed and their working capacity has been maximized.

Our product, which has a 30 m3 rock feeding feature, is one of the special work machines that our company put forward with its quality and experience. Our product, which is durable and ideal for long-term use, is produced in accordance with CE standards and does not contain any substances that may endanger human health.

Primary Impact Crusher

FABO primary impact crushers are designed to crush soft and medium hard stones with high rotor speed. It is considered as the heart of the mobile system it is on. It ensures that all parts on the chassis work in harmony with each other, FABO quality, and wide warranty coverage, provides confidence and customer satisfaction with its 24/7 accessible support line.

With the help of high-speed rotating rotor breaking bars, the products poured from the feeder are crushed with the help of pallets. Hydraulically adjustable rods allow the products to be obtained in the desired size.

Liners and pallets prevent wear of the FABO primary impact crusher and offer a long service life. Protective linings can be easily replaced. And the service life can be increased by changing the direction of the pallets.

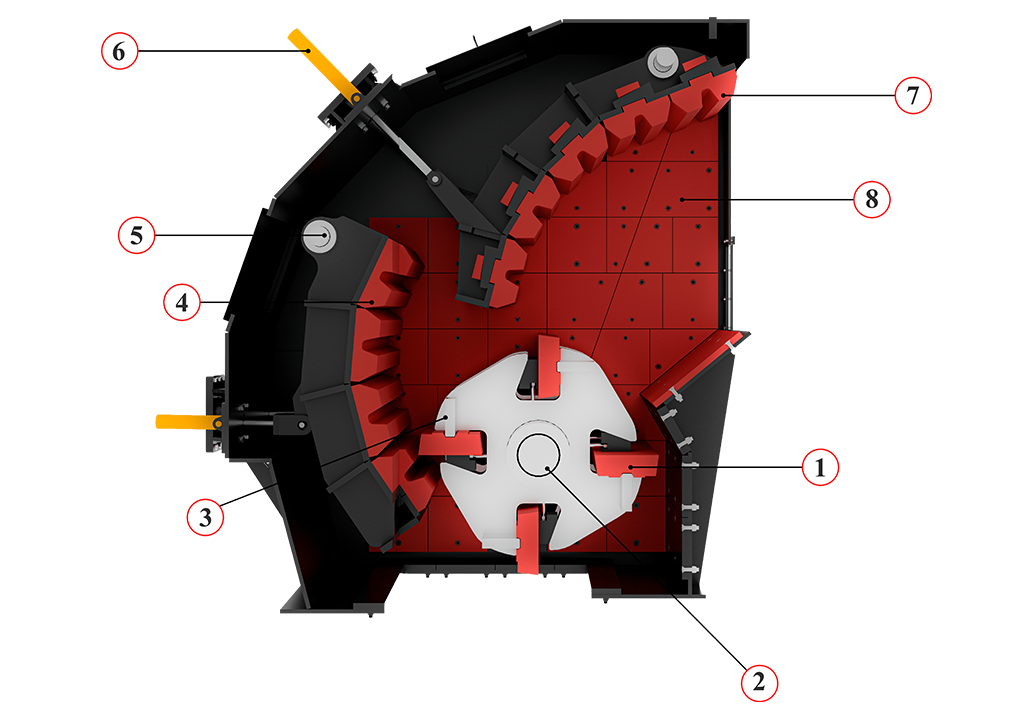

Interior view of the Primary Impact Crusher

| Turbomix-60 |

|---|

| 1- Crusher Pallets |

| 2- Crusher Rotor |

| 3- Pallet Holder Lock |

| 4- Crusher Lower Pendulum |

| 5- Pendulum Shaft |

| 6- Pendulum Adjustment Mechanism |

| 7-Crusher Upper Pendulum |

| 8-Side Linings |

Vibrating Screen

Fabo vibrating screen separate the products coming out of the crusher by means of 4 mesh wires of different sizes. When the desired dimensions are obtained, they are sent to the conveyor belts.

Thanks to the 2 bearings on it, FABO Screens keep the load distribution at the optimum level and offer a long service life. Thanks to 12 specially produced steel springs, it works in the most efficient way and provides maximum capacity.

FABO Screens are a combination of quality, reliability and performance; It provides a long service life even under the toughest conditions. Its unique location on the Pro-120 mobile crushing and screening plant allows it to work more efficiently. Fabo vibrating screen, which move in harmony with the impact crusher on which it is located, ensure that products in desired sizes are obtained in line with the demands.

Flap System

It is a special system that allows the crushed material to be taken with the help of the front stock band, after the necessary adjustments are made with the hydraulic adjustment pendulums of the Primary Impact Crusher in order to receive material from the direct crusher.

According to the desired product dimensions, pendulums can be adjusted to receive products such as 0-31 / 0-63 / 0-150 mm.

The flap minimizes production time with its unique position just in front of the sieve.

In addition, when it is desired to obtain a uniform product with the flap system, it disables the vibrating screen and prevents the screen from wearing out.

Woobler Feeder (Optional)

Wobbler feeding equipment is designed to prevent damp or sticky material coming with rough stones and minerals from entering the facility and disrupting the system in stone crushing and screening plants. If the wet and damp stones circulate in the facility, they can reduce the efficiency of the crusher, even if they do not completely stop the machines from working.

The working principle of wobbler feeders is based on the proper structure of these moist, wet and sticky materials before they enter the crusher. The equipment, which is designed especially to prevent blockages seen in sieves and feeders, works with the principle of rotating in the same direction and in a synchronized way by leaving a small distance between the sequential discs designed in different forms. Although they work at low speed, they have a very high processing capacity.

Stock and Return Bands

Fabo folding type feeding, feedback, stock conveyor belts are the vehicles that send the right product to the crusher and the stock area according to the product’s recipe after separeting through the vibrating screen.

With its foldable structure, it minimizes the dimensions of the machine it is on. Optionally, the number and length of tapes can be increased upon the request of the user.

10 mm EP 125 4-ply Band elastics, moving on 4mm st 37 Twisted Sheet, perfectly transport the aggregate coming out of the sieve to the area desired by the user in the most efficient way. The band tires, which are produced resistant to wear, will never let you down and offer a long service life.

Automatic Lubrication System

The Automatic Lubrication System is the system in charge of sending the grease that is reduced during the use of the crushing and screening plant and needs maintenance to the relevant part.

It distributes the grease evenly to all components of the mobile crusher that needs lubrication and provides perfect lubrication.

The automatic lubrication system, which provides great ease of maintenance, finishes the lubrication process in seconds without the need for manpower. It allows to use the Mobile Crusher Plant in the most efficient way.

It uses the amount of oil in the most ideal way during lubrication and minimizes the maintenance cost of the user.

Hydraulic System

Hydraulics is the system that enables the parts on the crushing and screening plants to move easily. Opening, closing and moving the machine’s carrying legs, feeding bands, bunker covers and crusher feeder can be given as examples.

Hydraulic System Working Principle:

With the movement of the control arms, the hydraulic oil in can activate and the material to which the hydraulic system is connected the desired direction.

Automation System

PRO-120 Mobile Crushing and Screening Plant is controlled by a full automation system. Thanks to the automation system panel on the machine, the working mode of the machine is adjusted. The working principle of the machine can be easily adjusted according to the shape of the material loaded by the user into the vibrating hopper. Many features such as Crusher Rotor Speed, (Optional) Woobler Feeder Speed, Bunker Vibration Speed, can be adjusted with the automation system.

The automation system, created by Fabo engineers, has been put at the disposal of its users in its most up-to-date form, taking into account all the tests performed from production to delivery.

It offers the opportunity to control the machine from anywhere in the world by using the remote connection feature with internet connection.

The automation system that allows you to use the Mobile Crushing and Screening Plant in the most efficient way has been prepared with PLC and serves its users with the most advanced state of technology

Brake Axle System

The main factor that enables the Pro-120 Mobile Crusher Plant to be moved easily is the axles at the rear. The load distribution of the crusher is calculated by our engineers and the number of axles and their position are determined.

Shipping

Fabo PRO-120 Mobile Crusher Plant minimizes the time and cash loss of the user with its ease of transportation. The PRO -120 Mobile Crusher Plant developed by our engineers can be easily moved on a single chassis with a truck. Fabo PRO-120 Mobile Crusher Plant, which is moved on 3 axles, is ready for transportation in 10 minutes.

The PRO-120 Mobile Crushing and Screening Plant, which we have created as a result of 18 years of knowledge and work, has been designed in the most ideal way for the user with its crushing and screening capacity and easy transportation.

The brake system in the axle system has increased the life and property safety of the user to the highest level and has written its name in the sector with gold letters with 0% accident rate.

Fabo PRO-120 Mobile Crushing and Screening Plant, which comes to the transport position without the need for manpower, is the leading crushing and screening plant in the sector with the highest transportation speed.