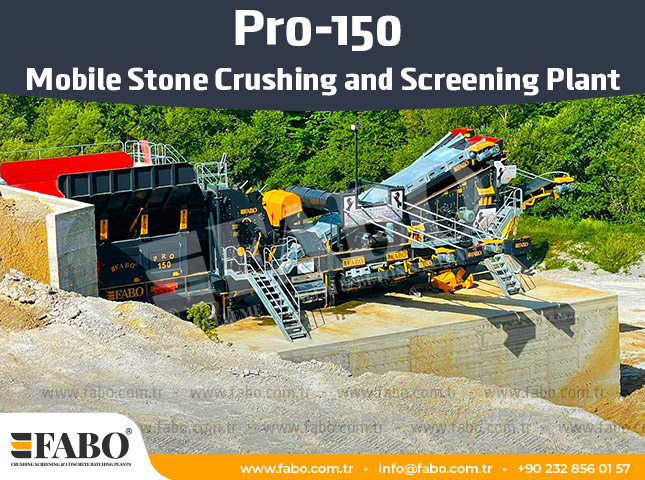

Pro-150 Mobile Stone Crushing and Screening Plant

Pro-150 Mobile Stone Crushing and Screening Plant; It has an average crushing capacity of 250 to 350 tons of material per hour. This capacity, which can change according to product features and dimensions, can be increased when necessary according to the demands of the enterprises, and special construction equipment can be produced for customers.

Pro-150 Mobile Stone Crushing and Screening Plant; The work machines in the facility, which has a hydraulic system, can be easily dismantled and relocated. This machine, which has the characteristics of a fixed crusher plant, is an ideal machine for businesses that do not have a specific working area or have a limited working area.

With this machine, you can do more than what you can do in stationary crushing and screening systems. The feature of mobile facilities is that they are easy to transport and set up. Immediately after the completion of short-term works, it can be transported to different sites with a single truck and the installation of the facility can be done within the same day. It is currently accepted as one of the most preferred machines in the world and in Turkey.

What is Crusher?

It is quite difficult to break mines and large rocks. Large and powerful machines are used to break these mines and rocks. The stone crushing and screening machine, which is used to turn large stones and rocks into small pieces, is called Crusher. Depending on the size or duration of the work, machines that can be used as fixed crushers or mobile crushers are produced. While the fixed crusher is suitable for long works, the mobile crusher is a preferred machine for short-term works.

The stones are reduced and turned into raw materials for the construction industry. Stones obtained in works such as roads, bridges and infrastructure are used. Fixed crushers are preferred because the stones extracted from quarries or mines are large.

Mobile crushers are used at the construction site. The broken stone pieces can be turned into smaller pieces if desired. Mobile crushers are used because construction sites are short-lived. When the existing construction is completed, it can be easily dismantled and taken to the new construction site.

Stone Crushing and Screening Plant Features

Since today, people have been working to make different structures. Different materials are used in making these structures. The substances that help to form these structures occur with basic building materials such as iron, concrete and brick. In particular, concrete is used in most parts of structures. With the strong structure of concrete, its life will be long and solid.

For the small stone pieces required for ready-mixed concrete, it is crushed by stone crushing and screening machines. The crushed stones are sorted according to the appropriate dimensions. Thus, different sized stones can be used for different areas where needed. The machine that is important at these stages is the stone crushing and screening plant. Let’s examine the features of stone crushing and screening plant together.

“Pro-150 Mobile Stone Crushing and Screening Plant”

- Production Capacity is 250-350 tons.

- Maximum feeding capacity is 800 mm

- Impact crusher rotor size is Ø1200×1500 in diameter.

- Vibrating sieve size is 2300×5500 mm in diameter.

- Total engine power is 425 kW.

- Generator option size is 700 kvA.

Having these features, Pro-150 is the most used stone crushing and screening machine in Turkey and in the world. FABO, “PRO-150 Mobile Crusher Plant” reduces the user’s time and cost to minimum levels by providing ease of transportation. It can be transported on a single chassis with a truck. The mobile facility is ready for transportation within 10 minutes.

Pro-150 Mobile Stone Crushing and Screening Plant Prices

The stone crushing and screening machine, also known as the crusher machine, is used to break up and break the large stones and rocks coming out of the mines and stream beds. Types of crushers produced according to the field used may differ in price. There are 2 different types of stone crushing and screening machines. You can choose according to the size of the construction site or the duration of the work done. For example, if the construction site is narrow and the duration of the work is short, it is appropriate to choose a mobile crusher. If your field is large and your working time is long, a stationary stone crushing and screening machine is preferred.

The price of Pro-150 Mobile stone crushing and screening machine varies, taking into account many factors. The reason is that these machines are quite large and complex facilities.

The features of the product, which includes different equipment and desired to be obtained, must be produced by choosing the structure and size of the project. Therefore, a fixed price cannot be said for these machines. You can request information by contacting us at FABO Global’s contact addresses to learn the price of the machine you want to buy in the dimensions you want.