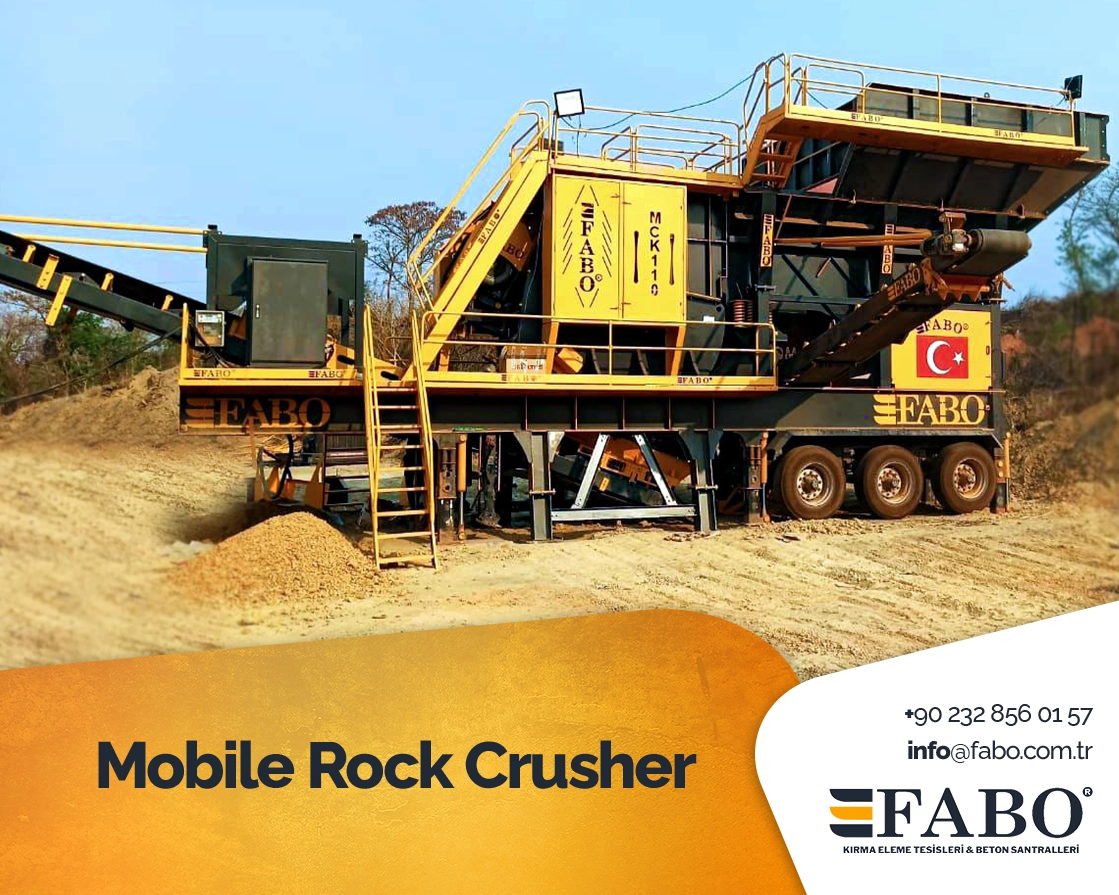

Mobile Rock Crusher

Mobile rock crusher solutions are used in crushing and screening plants; basically consists of components that are used to break stones or rocks. Crusher machines are commonly known as crushers . A crusher can be examined in two groups as fixed or mobile.

Mobile rock crushers provide high flexibility in terms of portability. This product group, which is smaller and lighter, provides high mobility in project areas. Thus, both space can be saved and the demand for human labor is reduced. Today, ready-mixed concrete is needed in many areas such as the building/construction sector. Some elements, especially aggregate, are needed for concrete production. Thanks to a stone crushing machine, aggregate production can be done easily.

Mobile Rock Crusher For Sale

A mobile crusher plant consists of some components, mainly various types of crushing machines . In mobile facilities, the main point is easy transportation and installation; production performance comes to the fore in fixed crusher plants. You can find more information about mobile and fixed facilities from the table below.

| Mobile Crusher Plant | Fixed Crusher Plant |

| It is suitable for short term projects. | It is mostly preferred in long-term projects. |

| It may be preferred if the project is planned to continue in more than one region. | It significantly reduces the need for human labor. |

| They are relatively small in size. Thus, it saves space. | They are facilities operating with extremely high performance. |

| It can be easily transported with the help of a truck. | Fixed facilities can also be moved, but this is more difficult and costly. |

| It can be made more functional thanks to components such as pallets. | It can provide high gain in long-term use. |

| Fabo produced the world’s largest mobile crusher with the Pro-150 model. | Just like in mobile plants, it can be enriched with optional components such as vibrating screen and cement silo. |

Mobile Stone Crusher

Mobile crushers break many different sizes of stones or rocks, making them smaller. The result of this process is the accumulation of small-sized stones and sand. This mixture is called aggregate. Concrete is obtained when aggregate is mixed with water and cement in appropriate proportions.

A mobile rock crusher can be examined under three different groups according to its working principle.

- Mobile jaw crusher: It is generally preferred to crush hard materials with high silica content such as granite and basalt. The reason why these machines are called jaws is that they work with a mechanism resembling a jaw. Stones stuck between two plates, one of which is fixed and the other is movable, are broken and made smaller. It is often needed in mining, quarries, recycling facilities.

- Mobile impact crusher: It can break many materials from soft to hard. It is preferred in mines, recycling areas or in the manufacture of sand and gravel. It works by applying direct crushing force instead of pressure.

- Mobile cone crusher: It is generally preferred for breaking materials from medium to high hardness. It breaks the materials by cutting or compressing.

Crawler Mobile Crusher

Crushers with added pallets increase portability to higher levels. Thus, the machines that can be moved very easily on the project site can cover a distance of 1 km in 1 hour. This distance is quite good for machines with tons of weight.

The components of this crusher are assembled on a hydraulic motor tracked chassis. The use of tracked mobile crushers enables companies to allocate a lower budget for infrastructure, operation and transportation. A tracked mobile crusher plant, single-chassis order:

- feeding hopper

- vibrating sieve

- Generator feeding and stock conveyors

- Control unit

It consists of the components that can be listed as working in harmony. So what are the advantages that make this facility stand out?

- Provides versatile mobility.

- The sieving capacity is extremely high.

- It can be easily steered with the help of the remote control.

Mobile Crusher Prices

The machines that make up the stationary and mobile crusher plant can be divided into three according to the level of crushing the materials.

| Primary Crusher | Secondary Crusher | Tertiary (Tertiary) Crusher |

| It roughly crushes the materials. | It can break the materials obtained as a result of primary crushing again. | These machines, also known as sand machines, can reduce the material to a sand size. |

| It shows the highest performance in mines with low and medium hardness levels. | It is preferred for breaking medium or high hardness material. | It has high impact power. |

| material to the desired cubicity level. | It can bring the work material to the desired fineness level. | Materials such as sand obtained are used in asphalt plants and concrete plants. |

mobile crusher prices

- From the selection of optional components in the plant,

- From the technical features and working principle of the preferred machine,

- Due to reasons such as the supply and transportation of some raw materials from abroad, the exchange rate

It can be affected. You can contact us to get up-to-date price information about our mobile crusher models for sale and to forward your purchase requests.