Mobile crusher plant is very useful for different projects or for the same project to continue in a different region for certain reasons. Because these plants are designed to be carried easily.

Mobile crusher plant production is quite durable when it is made by experienced companies. A variety of materials and techniques are also available for extra durability. Fabo products are produced by considering quality and reasonable price performance.

Mobile Stone Crusher Plants

Facilities are mobile crushing Also known as plants. Mobile crushers are manufactured to withstand the toughest physical conditions. Its adaptable and portable structure for different needs provides a great advantage for businesses operating in more than one sector.

So What is a mobile crusher? The production capacities of these machines are quite high. Being portable doesn’t compromise on performance. A mobile crushing plant has all the necessary equipment on a single chassis. Such a facility offers high efficiency for companies operating in construction sectors such as waste recycling, mining, road construction.

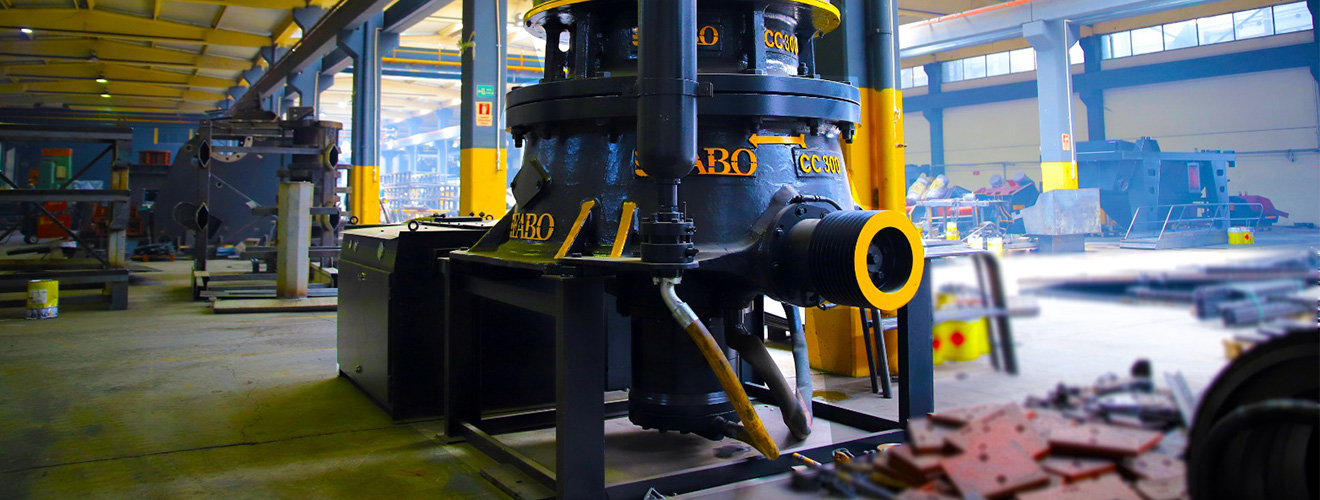

Fabo, with its 19 years of experience, has reached 6 continents mobile crushing and screening plant makes sales. These are the crusher machines with the strongest technical features on the market. Mobile stone You can review our crusher solutions from the list below:

- mobile primary crusher

- mobile secondary crushing and screening plant

- mobile vertical shaft crusher

- mobile container type jaw crusher

- Crawler crusher plant

- Crawler screening plant

- Pro series mobile crusher plant

- MCK series mobile hard stone crushing plant

- mobile tertiary crusher

- mobile crusher plant

Mobile Crusher plant for Sale

The tools in these facilities ensure that large pieces of rock or stone extracted from quarries or mines are reduced to the desired dimensions. These facilities are frequently preferred for the production of aggregate, which is the raw material of building materials.

A crusher machine can be divided into three depending on its purpose and the dimensions to which it will shrink the stone. These:

- primary crushers

- Secondary crushers

- Tertiary crushers

Primary crushers roughly shrink large rocks. These slightly reduced materials can be used directly or reprocessed in secondary crushers. Tertiary crushers are used when much smaller pieces, including grit size, are required.

Fabo, mobile crusher It owes its leading position among manufacturers to its production experience. Fabo has exported these products to around 100 countries. It has produced so much that it has become an international company that sets the standards in the market. Fabo sells mobile crusher plants in different models for different needs.

Mobile crusher The price may change according to the technical features of the product, the periodic exchange rates and the additional services requested with the product. You can contact us to get detailed information about prices and features and to request an order.

Track Asphalt Mobile Cone Crusher Plants

The machines used in concrete crushing plants are also called asphalt crushers. This is because it can also be used for asphalt recycling. Facilities have many functions for different purposes.

Asphalt plant is the facility used in road construction and asphalt works. There are both mobile, that is, easily transportable and fixed asphalt facilities. In the plants , the hot asphalt mixture required for laying on the ground is obtained.

Having smooth and solid roads is very important today. In this way, the rate of traffic accidents can be reduced and the possibility of damage to vehicles due to bad roads is prevented. In addition, the distance between regions can be shortened or the flow of traffic can be relieved by constructing new roads. Although different types of roads have been tried recently, asphalt has come to the fore as the most used method.

Asphalt roads are of high quality and durable. Moreover, the cost is also affordable. Asphalt production facilities produce the material required for asphalt roads. This material consists of a mixture of materials called aggregate and bitumen. The asphalt plant heats the aggregate and mixes it with bitumen. Depending on the type and quality of the asphalt to be produced, the mixing ratio of the materials may also be different. Fabo also develops solutions in this field with its asphalt production plant models.

How Do I Start A Stone Crusher Business?

This is a question whose answer is often sought. Experienced facilities do the stone crushing work in the most accurate and quality way. However, new production facilities can be created with expert engineers and qualified technical staff. For this job, first of all, you must have various qualifications financially.

To build a stone crushing plant, you will need to buy or lease crusher machines unless you have a company or organization that manufactures the capable machines. Entrepreneurs can produce by establishing their own facilities through purchasing. They can also earn money by selling the materials they produce.

It is not necessary to start a new business or be an entrepreneur for this. If you want to operate in different fields as a company, you can enter the stone crusher business. For example, asphalt production or the production of aggregate material brought to certain dimensions for the construction and mining industry.

To start the stone crusher business, you can get information and support from Fabo and make a good start by purchasing the most functional and innovative facilities in its field.

How Much Does a Crushing Machine Cost ?

Crusher machines have a wide range of products. This diversity has been formed according to what will be obtained with the machines and what sizes will be obtained. For example, if it is desired to obtain very small materials from the rocks or stones to be broken, tools called tertiary crushers are preferred.

Primary crushers are required if the crushing required consists of only slight size reduction . As mentioned before, if more than one job will be done in different regions, portable rock crusher, stationary crusher machines are preferred even if it is planned to work in the same region for many years.

Well how many types of crushers plants are there? Crushers also differ according to their working principles. Basically, if we collect them in three groups:

- Jaw crusher machine

- cone crusher machine

- impact crusher machine

These machine types are also available in many models with different technical features. As can be seen, there are many factors that determine the cost of a crusher machine. Mobile crusher price varies according to the mentioned factors. The first way to predict the price is to determine which features of the machine will be preferred. If you want to choose the most suitable machine for your needs and get price information about it, you can contact us

How a Stone Crusher Plant Works?

Mobile crushing plant or mobile crushing How does machine work? We have examined portable facilities in three groups according to the working principle of machines. Now let’s look at how these machines work.

Mobile cone crushers can be used to crush a wide variety of stones. It is functional for breaking and shrinking stones with high abrasiveness or softer rocks. Due to their mobile structure, transportation costs are very low.

These breakers do not have difficulty even when breaking hard rocks such as basalt, andesite, granite. They can be used as primary, secondary and tertiary crushers. In addition to being robust, they are very durable machines. They offer a long service life. Since they are products with advanced automation systems, they are extremely easy to use. It has an affordable price compared to its features. Operations such as maintenance and cleaning can be done easily.

Jaw crushers use compression force to break the material into smaller states. The material is compressed between the fixed and movable surfaces, and the surface force of the movable part achieves the crushing. These machines with a long service life provide high profit to the business. They can be used by a single operator.

Mobile impact crushers, on the other hand, are mostly preferred for crushing materials with low and medium hardness. Their capacities are quite high. The breaking mechanism works as follows. First, the stones break by hitting each other. These stones are then broken into smaller pieces by hitting the plates on the upper and lower wings.

Impact crushers provide a higher rate of small size material output compared to others. Moreover, it does this without compromising the structure or quality of the substance.

Fabo Crusher

Fabo breakers are machines used around the world, known for their robustness and long service life. It manufactures a wide range of products from the Small mobile crushers family to portable crushers.

best mobile rock researched by many interested The answer to the crusher query actually differs from company to company. What material or materials do you want to shrink with the mobile stone crusher? At what degree of reduction do you want to do this? The answers to your questions will direct you to the best Fabo stone crushers.

For example , let’s say you want to do secondary crushing and you will be working with hard rocks such as andesite. In this case, impact crushers, which are mostly preferred for medium and soft materials, will not be a good option for you. Cone crushers, on the other hand, will be a good choice as they are very powerful crushing machines and are also suitable for secondary crushing. Cone crushers were the best mobile stone crushers in this scenario. It remains to choose the mobile cone crusher model with various technical features.

Fabo has both mobile and stationary crushing, screening and washing plants and all the product range required in these plants.

Fabo Mobile Crusher Models

Some mobile crushers You can find our plant solutions in the list below:

- 110 Mobile Screen Primary Jaw Crusher

- 90′ Mobile Screen Primary Jaw Crusher

- 60′ Mobile Screen Primary Jaw Crusher

- Mobile Primary Crusher with 180 PDK

- Mobile Primary Crusher with 150 PDK

- Mobile Primary Crusher with 100 PDK

- MJK-110 Mobile Primary Jaw Crusher

- MJK-90 Mobile Primary Jaw Crusher

- MJK-60 Mobile Primary Jaw Crusher

- MJC Series Mobile Crushers

- PDK Series Mobile Crushers

- MIC-100 Mobile Primary Impact Crusher

- Pro Series mobile crusher plant

- MCK Series mobile crusher plant

- Mobile Vertical Shaft Crusher (MVSI and VSI Series)

CTC-60 Mobile Container Type Jaw Crusher

Vertical shaft Impact Crusher

Mobile vertical shaft impact crushers ensure the material to be crushed by means of high-speed rotors and anvils. These breakers are available in models with different capacities. So they can be used in both large and small projects.

Energy expenditures are low. It is easy to maintain and use. It is suitable for working in all climatic conditions.

- asphalt aggregate

- Gravel

- Annual

- road base

They are useful machines to obtain. With this machine, which can also be used in the mining industry, materials such as perlite, magnesite and iron ore can be crushed. Vertical shaft crushers are mostly suitable for secondary or tertiary crushing.

Fabo have model names such as MVSI and VSI. For example, the production capacity of the MVSI -700 model crusher is in the range of 100-150 tons. It has a vibrating sieve of 1500×4000 mm dimensions . The total engine power of the product, which comes with a generator optionally, is 180 kW.

In the VSI-1000-OR model, there are 2 motors operating at 200-250 kW. The hourly production capacity of 19 tons of product varies between 150 and 400 tons. Vertical shaft crushers have emerged as a result of the need for fine material crushing with low operation cost.

Concrete Crusher

Concrete crusher machines are generally used for breaking concrete structures, road projects and recycling plants. They are machines that shred the concrete until it reaches the desired dimensions. Tracked models of these crushers are also available. It is easy to transport.

Tracked models provide convenience in the work area as they are in a movable structure. Asphalt crushing work is also carried out by this machine. They have high mobility.

Concrete crushing plants are frequently preferred in demolition works. It usually has small dimensions. It can be carried easily on a single chassis. The crushers used in concrete plants can be jaw, conical or impact type. You can contact us to get information about Fabo production models or to place an order in this area .