Jaw rock crusher for sale are preferred in many areas, especially in mining, quarries and recycling facilities. Crushers are also known as crushers . Crushers break stones or rocks in order to bring them to the desired dimensions.

Jaw rock crusher machine models for sale are manufactured with different technical specifications and in accordance with the needs of the customers. Although a jaw crusher can crush both soft and hard rocks, it is generally preferred for reducing hard and abrasive materials.

Jaw Rock Crusher Prices For Sale

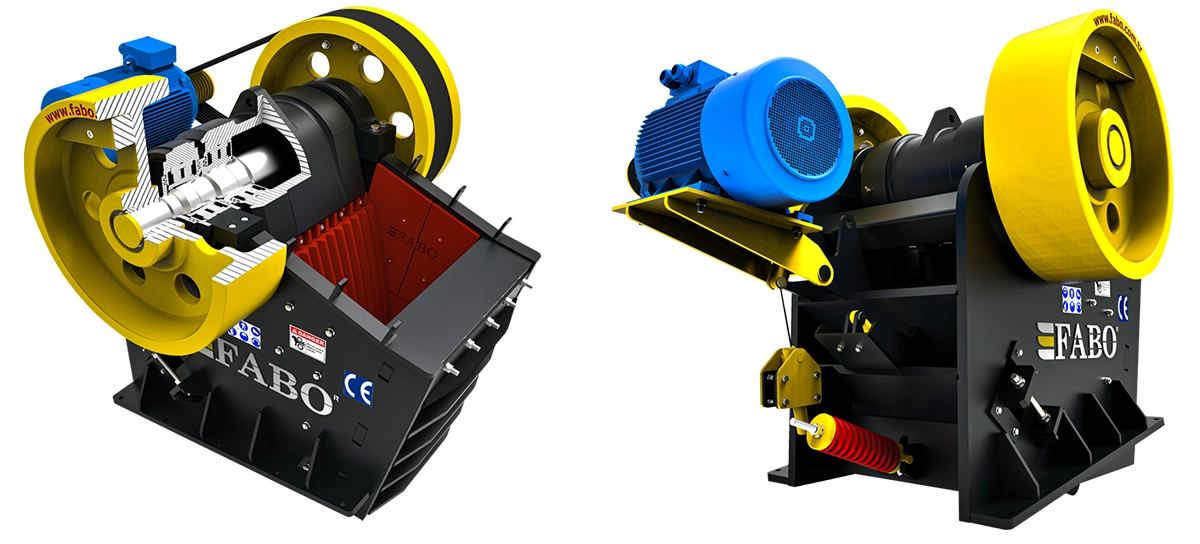

Jaw crushers stand out with their extremely strong construction. These machines work like a jaw grinding food with the help of teeth. Materials stuck between two jaws or plates , one of which is fixed and the other is movable, are broken down and reduced.

It is an extremely successful machine type for breaking hard materials with high silica content, including granite, basalt, limestone and marble. crusher prices

- From the portability of the machine,

- From its technical features,

- From the material reduction ratio,

- Optional components requested by the company/enterprise that will make the purchase.

It can be affected. The details of the project where the crushers will be used clarifies exactly which devices may be needed. Fabo also provides consultancy to its customers in this regard. You can easily contact us through our contact information on our website.

Types of Jaw Crusher Machines for Sale

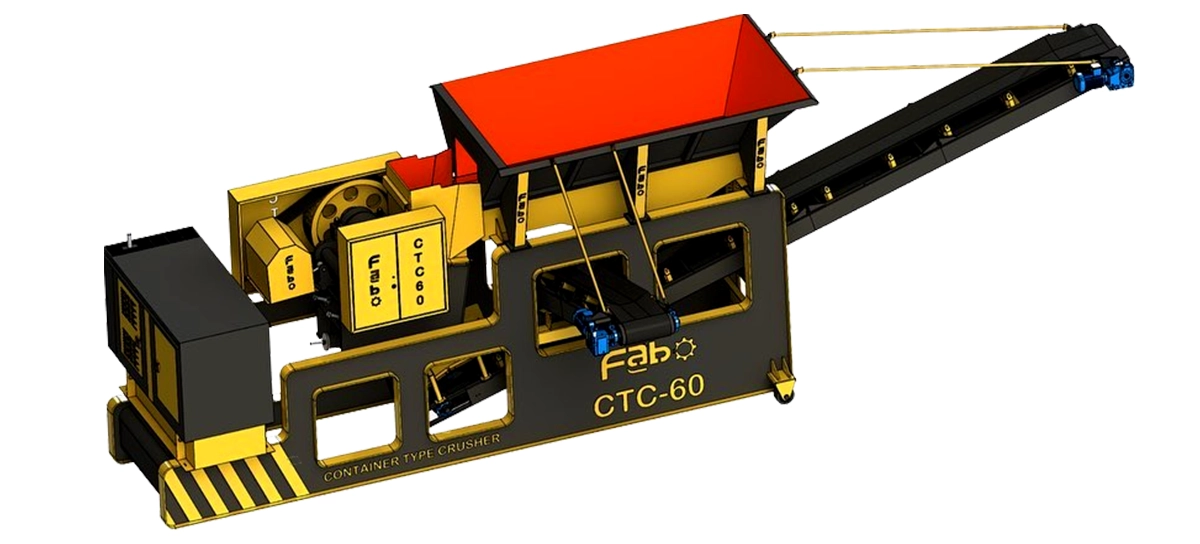

A jaw crusher can be divided into mobile or stationary based on its portability. Mobile jaw crushers can be moved easily with the help of a truck. At the same time, these machines also have crawler options. Thanks to the pallets, the machine can easily move in multiple directions on the work site.

Mobile crusher plants are mostly preferred in short-term projects. If the project will continue in more than one region, mobile product models will be extremely suitable. Fixed jaw crushers are suitable for long term projects. It gives importance to high performance, but unlike mobile crushers, it is more difficult and costly to transport. Both crusher plants can be enriched with optional components that increase efficiency, such as a vibrating screen or cement silo.

The basic element in a crushing and screening plant is the crusher. However, sieves that take part in the classification of the aggregates produced are among the indispensable components. Fabo has an extremely wide range of products in this field. Thanks to the vibrating screen, crawler scalper screen and mobile screen options, similar sized pieces can be grouped together.

Jaw Mobile Crusher

Mobile stone crushers are basically divided into three types according to their working principles. These;

- jaw crusher

- cone crusher

- impact crusher

It can be sorted. Cone crushers are mostly used for the reduction of medium to high hardness materials. Impact crushers can be preferred for breaking both soft and hard materials . It is mostly used in mines, sand/gravel production or in the recycling industry.

Crushers can be divided into three groups according to their material reduction ratio.

| Primary Crushers | Secondary Crushers | Tertiary (Tertiary) Crushers |

| It roughly crushes the materials. | It can break the materials obtained as a result of primary crushing again. | These machines, also known as sand machines, can reduce the material to a sand size. |

| It shows the highest performance in materials with low and medium hardness level. | It is preferred for breaking medium or high hardness materials. | It has high impact power. |

| It brings the crushed material to the desired cubicity level. | It can bring the work material to the desired fineness level. | Materials such as sand obtained are used in asphalt plants and concrete plants. |

Jaw Fixed Crusher Plants

A jaw crusher has a choice of models that can work both stationary and mobile. High performance and durability come to the fore in fixed crusher plants. Thanks to these facilities, many processes are carried out automatically with machines and the need for human labor is reduced.

A crusher machine model has purchase options such as new or second hand . However, since there will be a certain amount of wear and tear on second-hand products, both their performance and lifetime will be low. New products are guaranteed machines with all kinds of technical service and spare parts support.

Fixed crusher plants, which have been operating for many years without sacrificing performance, increase their profits as they are used. In the jaw crushers category, we have models for all product groups. To send your questions and share your project with us, you can contact us via our contact information on our website.