| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR |

|---|---|---|---|

| MODEL | DIMENSIONS | MOTOR POWER | CAPACITY |

| FWF-1125 | 1150x2500 mm | 18,5 kW | 250-350 TPH |

| FWF-1150 | 1150x5000 mm | 2x18,5 kW | 250-350 TPH |

| FWF-1425 | 1400x2500 mm | 22 kW | 350-450 TPH |

| FWF-1450 | 1400x5000 mm | 2x22 kW | 350-450 TPH |

| FWF-1625 | 1600x2500 mm | 30 kW | 500-600 TPH |

| FWF-1650 | 1600x5000 mm | 2x30 kW | 500-600 TPH |

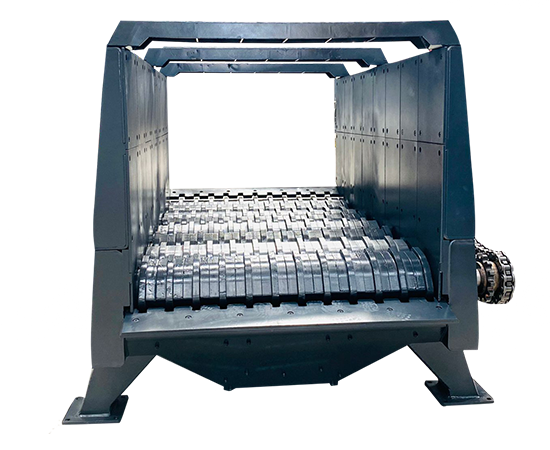

FABO Wobbler Feeder

FABO has succeeded in being the leading company in production and supply of crusher plant as a result of long years in the sector and large investments in R&D. FABO Wobbler Feeders are the best quality and technological feeders available in the market as well.

The shafts in the FABO Wobbler Feeder rotate synchronously to each other. With the help of this rotation, unwanted materials such as thin, sludge or waste materials are evacuated from the system. Thus, FABO Wobbler Feeder prevents unwanted materials from passing to the main crusher.

In order to avoid any performance loss due to the damp or muddy material processed in the crusher facilities, the wobbler feeder contains all the necessary qualities. While it has the potential to process without any problems for many years, FABO Wobbler Feeder stands out with its easy maintenance feature as well.

What is a Wobbler Feeder?

Crushing plants, known as stone crushing and screening plants, process coarse-sized stones and ores extracted from mineral deposits or stream beds. After these raw materials are brought to the crushing plant, they are transformed through many processes into a material called aggregate which is the basic material of the building sector.

Despite having a very complex structure, stone crushing and screening facilities consist of many machines and equipment working in synchronization with each other. Crusher plants are generally designed to process dry material. However, in some cases, wet stones brought from the stream bed to the crushing plants can also be processed. In these cases, the problem arises that the wet or sticky material clogs the sieves and feeders, so decreasing the plant’s operating efficiency. Wobber Feeder is the equipment designed to prevent such situations.

Working Principle of Wobbler Feeder

Wobbler feeding is designed to prevent the disruption caused by entering the moist or sticky material that comes with unprocessed stone and mines into the operation of stone crushing and screening plant. If wet and moist stones circulate within the facility, they may reduce the efficiency of the facility, even stop the operation of the machines completely.

The working principle of Wobbler feeders is based on the evacuation of these moist, wet and sticky materials before they enter the processing. It has been designed in different forms to avoid blockages seen especially in the screen and feeders. It works by turning shafts in the same direction and synchronously. Although they operate at low speed, they have a very high processing capacity.

Where to Use Wobbler Feeder

Wobbler feeders have a very important role in feeding the facility, especially by drying sticky and moist raw materials. Therefore, it can be used in crushing and screening plants for almost any stone type. The most preferred situations are given as follows:

- Facilities processing the materials brought from the stream bed. Stream beds contain quality pebbles and stones that are required in various areas. However, these stones may have intense moisture or mud. This is why wobbler feeders are frequently preferred in crusher plants where these stones are processed.

- Facilities processing moist ores extracted from mines. Stones and ores extracted from mines may be damp, muddy or wet due to different reasons. This situation leads to a decrease in the efficiency and productivity of crushing plant. Therefore, these types of feeders are frequently required in projects related with mines.

Specifications of Wobbler Feeder

Wobbler feeder is a machine that increases the performance and efficiency of crushing plants. It is designed for feeding large size materials and sorting small size materials. The general specificaitons of Wobbler feeders are as follows:

- The outgoing wet material is dried and conveyed to the crusher or screen

- It raises efficiency in crushers

- It prevents possible performance degradation

- It provides the transmission of the material to the primary crusher when necessary.

- It has the ability to clean itself.