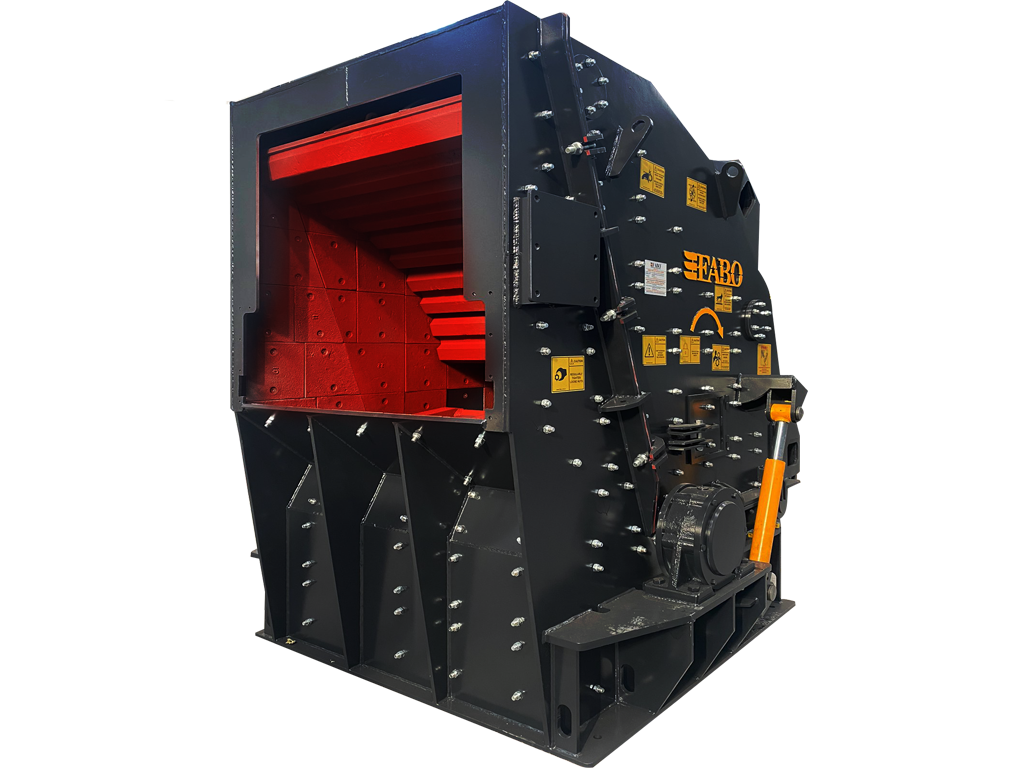

Secondary Impact Crusher

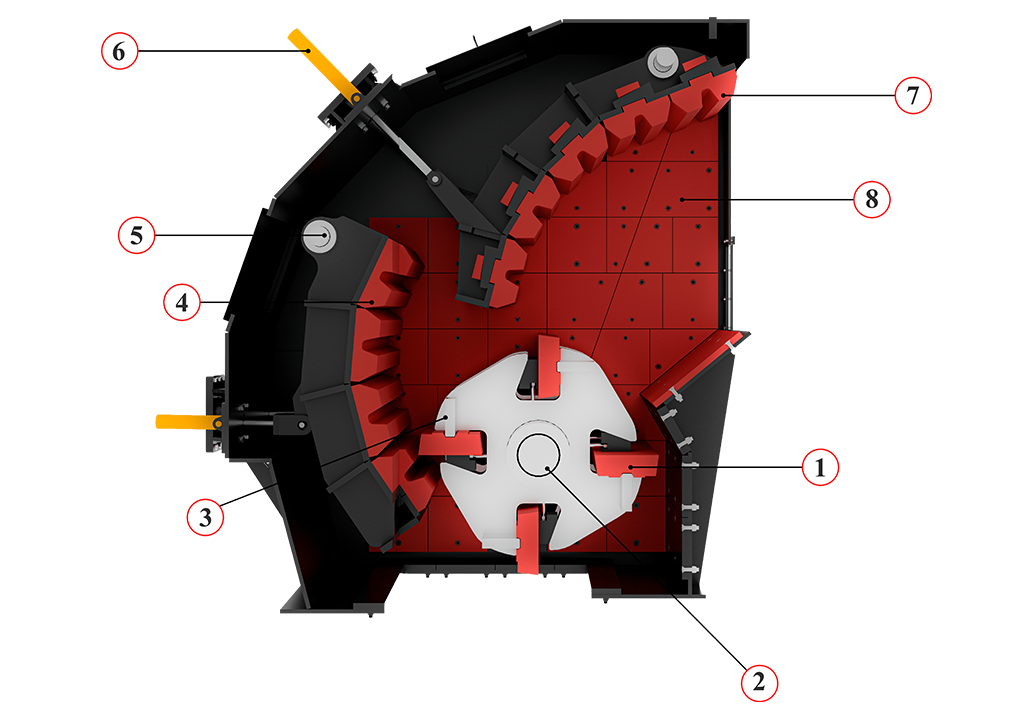

It breaks the products by hitting the pendulum with the rotor arms. It continues until the size specified in the automation system is achieved.

The secondary impact crusher, which is reinforced with high alloy chromium and bolted linings to prevent corrosion, serves its users for many years.

Maintenance:

Ease of maintenance and adjustment is one of the most important advantages of this type of breakers. The hydraulic body opening system, external adjustment of the crusher plates, easy pallet and lining replacement enable this type of crusher to be used easily in construction site conditions.

General Features and Advantages:

-High capacity

-High reduction ratio

-High rate of cubic and fine material production

-Ease of maintenance thanks to the hydraulic adjustment system

-Wear resistant lining plates

-The parts exposed to wear are protected by hardfacing welding

– Pallets and crusher plates are high Chromium and Manganese steel casting