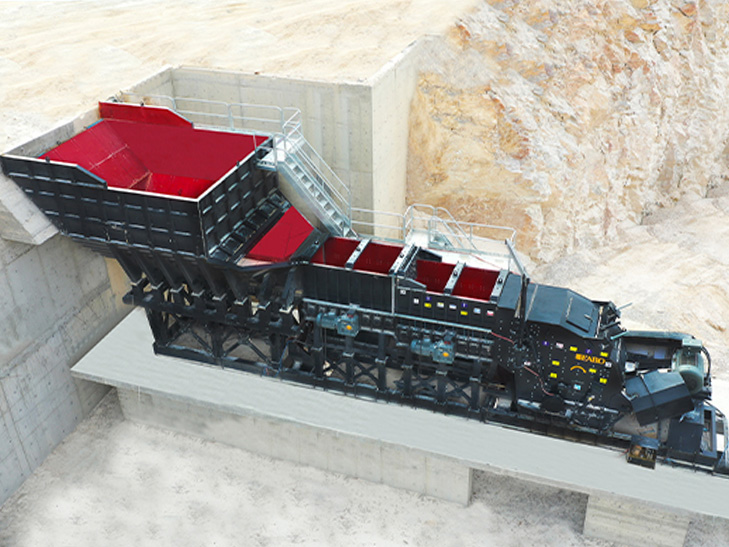

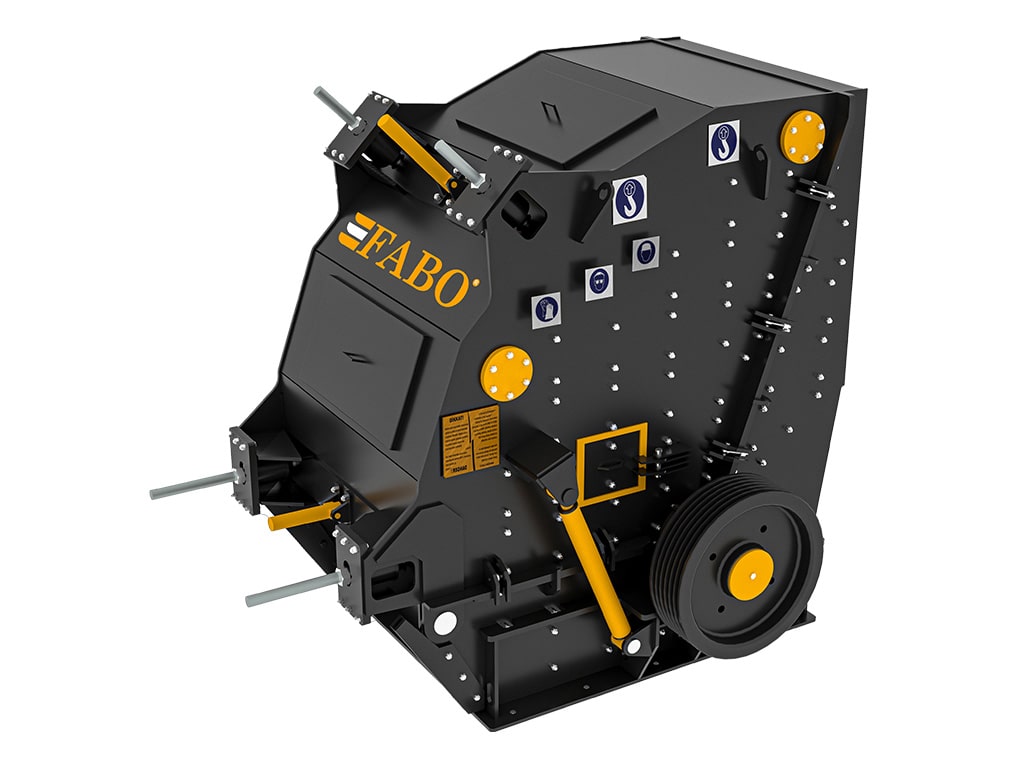

Designed to process large feed sizes and high capacity crushing, Fabo PDK impact crusher is suitable for primary processing of limestone materials or medium hard materials. It is very compact and it can achieve high performance and excellent cubicity of the crushed product.

The PDK crusher can replace the CLK jaw crusher when the feed material is particularly not hard and abrasive, because in addition to the high particle size reduction, it provides a higher percentage of fine grain. The maximum feeding size is designed depending on the size of the feeding opening