| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR | 5 |

|---|---|---|---|---|

| MODEL | EBAT | MOTOR GÜCÜ | SU İHTİYACI | KAPASİTE |

| DSHC-1224 | 1200x2400 mm /Pompalı | 2X3,6 kW Vibro Motor | 200-350 m3/h | 70 T/H |

| DSHC-1530 | 1500x3000 mm/ Pompalı | 2X7,5 kW Vibro Motor | 250-400 m3/h | 120 T/H |

| DSHC-1540 | 1500x4000 mm/Pompalı | 2X7,5 kW Vibro Motor | 300-450 m3/h | 160 T/H |

| DSHC-1840 | 1800x4000 mm / Pompalı | 2X9 kW Vibro Motor | 600 m3/h | 200 T/H |

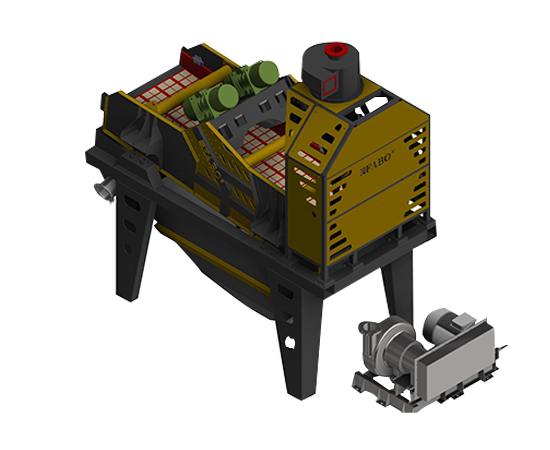

What is Dewatering Screen?

Concrete it is a component obtained as a result of mixing sand, cement and water in certain proportions and it is heavily required for the construction and building sectors. Sand, which is the basic material required for cement production, is produced in stone crushing and screening plants, also called crushing plants. The sand that is obtained from crushed large stones needs to fullfill certain standards in order to be used in the cement production.

In order to achieve these standards, sand must go through some stages. Apart from the crushing process of the sand into small pieces suitable for concrete production, it also needs to be screened and cleaned. In this same process the equipment that increases the quality of the sand in the crushing plants by drying it after washing is the dewatering screen.

Working Principle of the Dewatering Screen

The main task of the dewatering unit is to clean and dry the washed sand in a short time. The principle of doing this operation is as follows;

- The washed sand is first sent over the curved polyurethane panels.

- The material is moved upwards in the direction of 5 degree inclination with two vibromotors installed.

- The water stays where it is as the material climbs up.

- Creates a pool here

- Thus, water and other organic components adhering to the sand are thrown out of the screen.

- Water is also sent to the system for further use.

In this way the sand passing through the screen becomes ready for use as dewatered.

Where is the Dewatering Screen used?

The sand washing and dewatering unit is a necessary equipment to clean the sand, to create fine material, by screening it from sulfur, clay and organic materials, from the crusher used in the crusher plant. Because the structure of the sand directly affects the quality of the concrete to be obtained. Therefore, dewatering screen is important in producing the sand required to produce quality concrete.

Dewatering units are more used in;

- In projects where sand is produced for use in constructions

- In projects that produce sand used in industrial areas.

- In crushing plants producing sand for use in the construction industry

- In facilities that want to produce quality concrete sand

Therefore, the performance of this equipment, which has a very wide usage area, is important in terms of the capacity of the facility.

Dewatering Screen Charachteristic Features

The main feature of the dewatering units is to discharge the average 20% water held by the sand, which is subjected to the washing process, from the sand by passing through certain processes. Otherwise, the purification of the water from the sand is a process that can take weeks. On the one hand, there may be a stock problem in the facility area that continues production.

The other features of the dewatering unit, which is an important part of the screening and washing system, are as follows;

- Discharges the water absorbed by the sand in a short time

- Allows the sand to be purified from organic materials

- Increases the purity of sand

- Allows to obtain better quality concrete

- Lowers the firm’s inventory cost

- Increases the strength of the resulting sand

- As a result of the process, slightly moist material comes out.