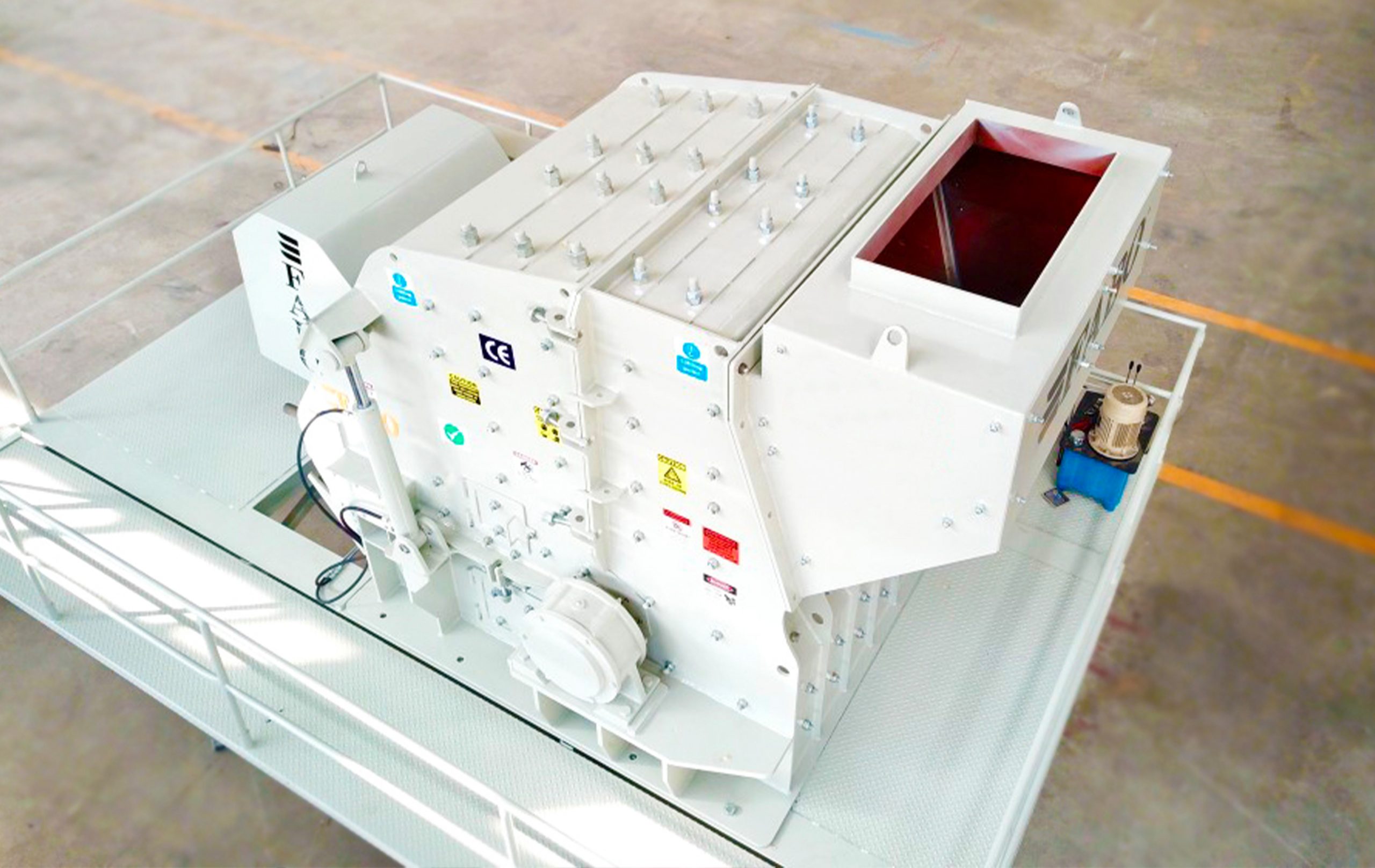

DMK series secondary impact crushers are our secondary impact crushers that pioneer the crushing of medium and high hardness materials. DMK crushers are designed to reduce wear costs while increasing capacity and cubic product volume.

High Performance, Easy Maintenance

Ease of maintenance and adjustment is one of the most important advantages of secondary impact crushers. The hydraulic body opening system, external adjustment of the crusher plates, easy pallet and lining replacement enable this type of crusher to be used easily in construction site conditions.

DMK-02 Secondary Impact Crusher

- Rotor Size: Ø 1120 x 1250 mm

- Maximum Feed: 450 mm

- Engine Power: 200 kW

There are 2 surveillance covers.

Gamak, Emtaş or equivalent engine brands are used.

Castings are used in high alloy chrome.

There are bolted wear liners to prevent crusher bottom groove wear.

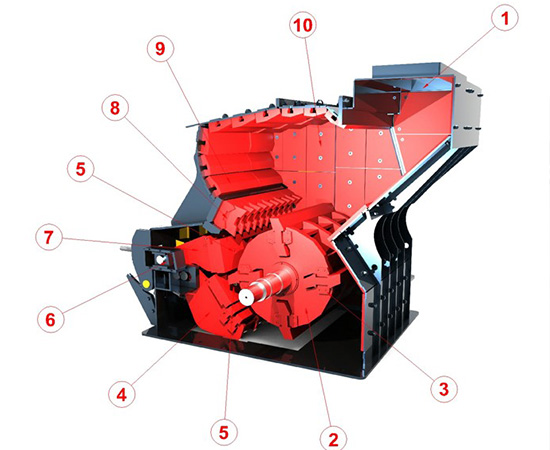

Inner view of the Secondary Impact Crusher

| Turbomix-60 |

|---|

| 1-Crusher Feeding Chute |

| 2-Crusher Rotor |

| 3- Pallet Holder Lock |

| 4- Bottom Breaker Adjustment Pandule |

| 5- Pallet Clamping Bolt |

| 6- Crusher Middle Pandule Adjustment Slıde |

| 7-Crusher Middle Pendul |

| 8- Crusher Middle, Upper Pandulate Castings |

| 9- Breaker Top Wall Pandules |

| 10-Breaker Side Linings |

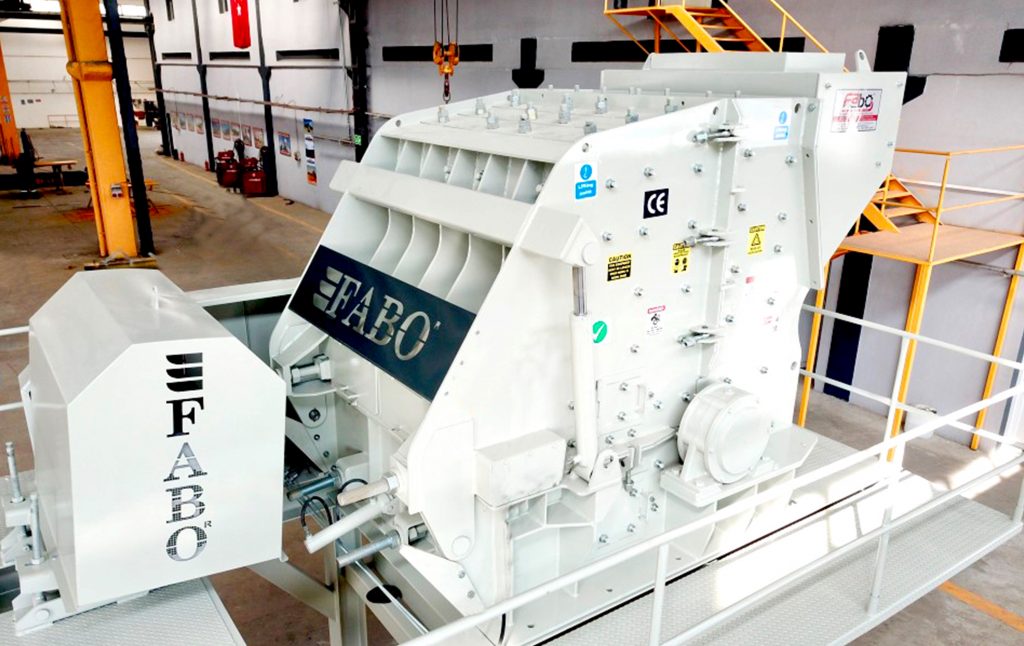

Secondary Impact Crusher Appearance

| Turbomix-60 |

|---|

| 1- Pendulum Sight Covers |

| 2- Pendulum Adjustment Stabilizer |

| 3- Pendulum Adjustment Stabilizer |

| 4- Pendulum Foot Slides |

| 5- Body Opening and Closing Piston |

| 6- Crusher Lower Adjustment Piston |

| 7- Lubricating the Crusher Bearing |

Strong References

FABO continues its services with its young, dynamic and professional team to produce durable facilities and to provide 100% customer satisfaction.

FABO, which has reached 2500+ exports in 100 countries, has added a new facility to its production.

Our Promotional Videos

Watch our promotional videos to get to know our facility in detail and learn about all its features.