Jaw crushers are generally used to crush hard and abrasive materials with high silica content, such as basalt, granite, etc.

The high flywheel speeds of our jaw crushers, their high performance, reliability, durability and user-friendly adjustment mechanisms brought about by the special geometry of their pitmans with safety plates and back blocks provide unique operating advantages to their users.

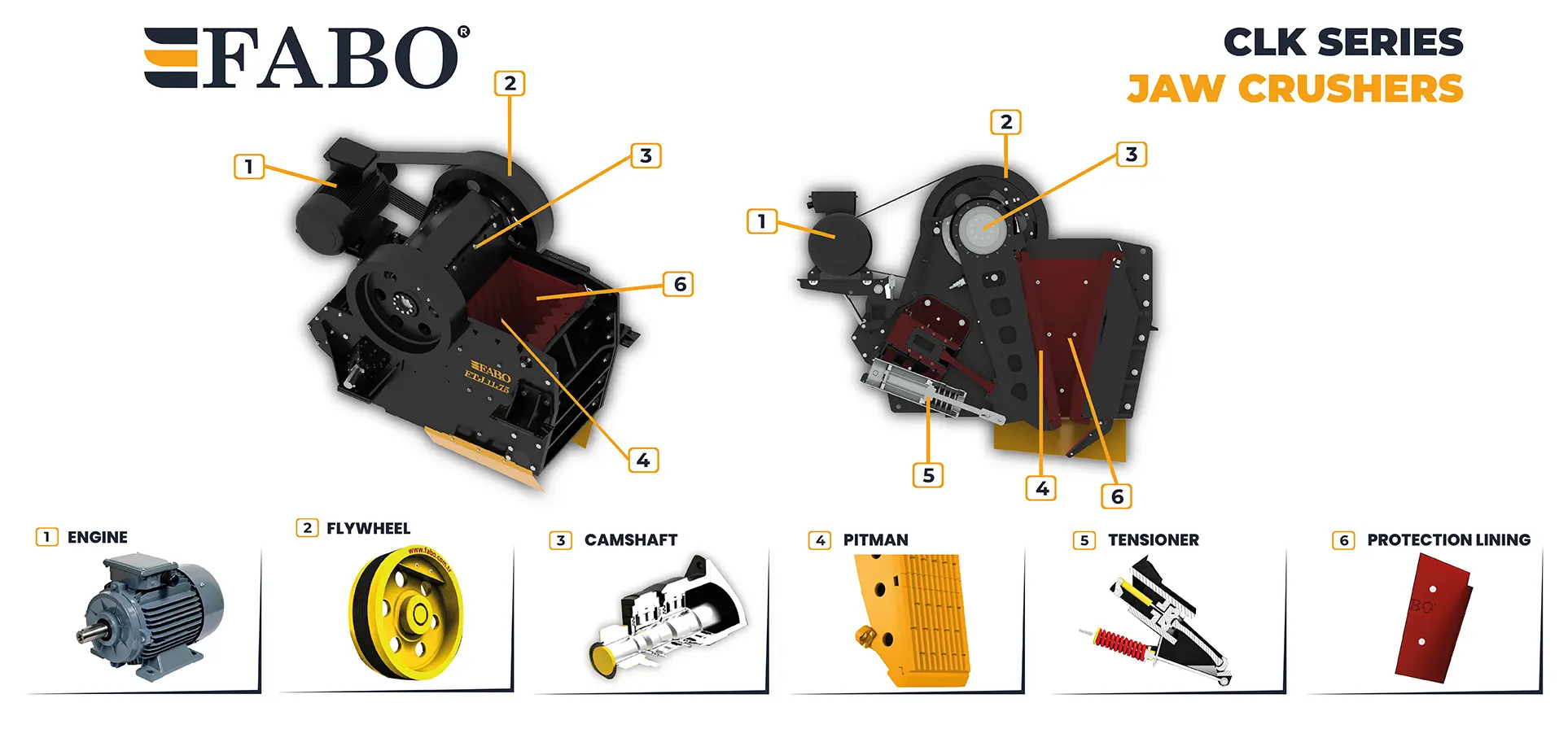

Parts of Jaw Crusher

1-Fixed Body: Fixed body protected against abrasions and hard impacts

2-Pitman: Its opening can be adjusted with the hydraulic system.

3-Linings: Prevents wear of the fixed body. It is fixed to the crusher body with a bolt, thus providing great ease of maintenance. It can be easily replaced by a staff member.

4-Flywheels: Provides maximum capacity with high rotation speed. Made of SFERO Casting

5-Eccentric shaft Group: The eccentric shaft allows the piston to move. Bearings are heat sensor protected.

6-Tensioner Device: It is the system responsible for changing the opening of the pitman. It can be easily operated hydraulically by one personnel.

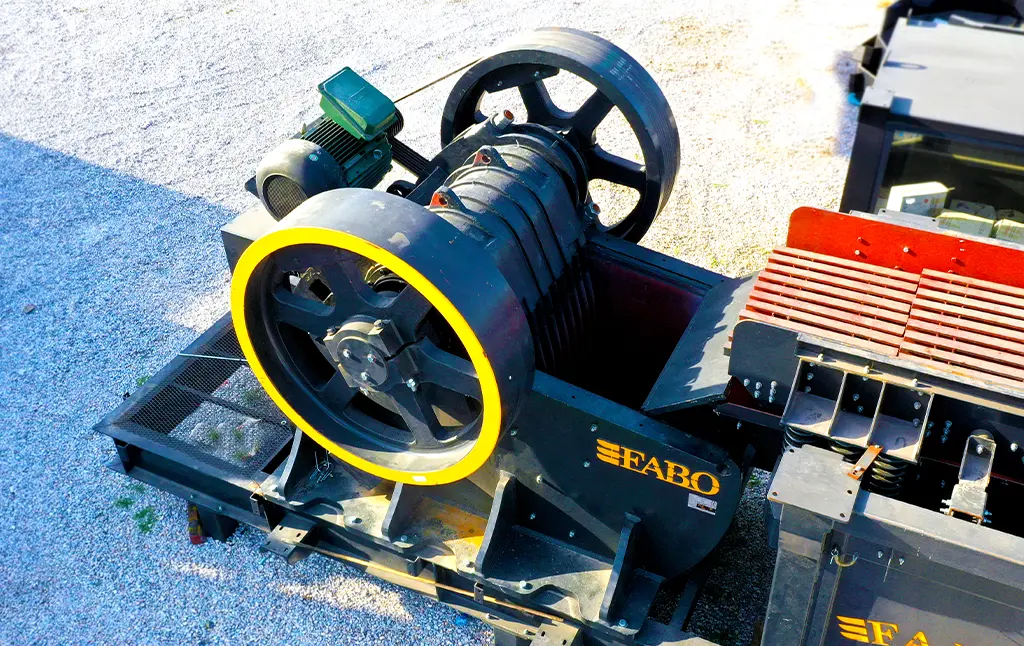

Jaw

Crusher

Portable

Pitman

800 mm

Maximum Feeding

132 kW

Motor

Strong References

FABO continues its services with its young, dynamic and professional staff to produce durable facilities and to provide 100% customer satisfaction.

FABO, which has reached 3500+ exports in 100 countries, has added a new facility to its production.