| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR |

|---|---|---|---|

| Vibrating Screen | 1530x4800 mm | Total Power | 110 kvA |

| Production Capacity | 220-400 TPH | Weight | 32000 Kg |

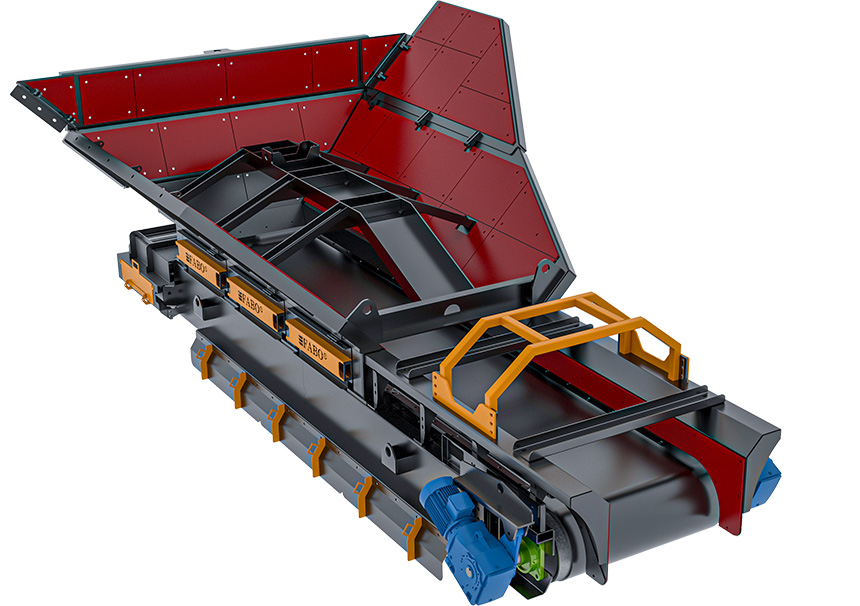

Tracked Scalper Screen

FABO Tracked Scalper is a crawler screening plant with high mobility, which can be moved in the desired direction with the remote control and it is designed in accordance with all difficult terrain conditions. The material which is transferred to the screen from the Tracked/Conveyor Belt feeding bunker, is screened in 2 different sizes and sent to the stock area with stock conveyor belts. The Tracked scalper provides maximum screening performance, works in harmony with crushing plants and is produced by FABO to provide endless customer satisfaction to its users.

Eliminates Infrastructure Requirement

Tracked Scalper Screen does not require an extra infrastructure as a production method, it is moved with a remote control and adapts to all difficult terrain conditions.

Tracked/Belt Feeding Bunker

It is the part in charge of transferring the material loaded on the Tracked/Conveyor Belt Feeding Bunker to the vibrating screen. The feeding bunker, which transfers 250-400 tons of material per hour, is equipped with superior features by FABO engineers.

Vibrating Screen

It separates the material of different sizes into the desired size and sends it to the stock area with stock conveyor belts. The vibrating screen, which screens in minimum 2 and maximum 4 different sizes, achieves maximum screening capacity thanks to the bearings and steel springs on it, and it screens up to 250-400 tons of product per hour.

Stock and Return Bands

With its foldable structure, it minimizes the dimensions of the machine it is on. Optionally, the number and length of tapes can be increased upon the request of the user.

10 mm EP 125 4-ply Band elastics, moving on 4mm st 37 Twisted Sheet, perfectly transport the aggregate coming out of the sieve to the area desired by the user in the most efficient way. The band tires, which are produced resistant to wear, will never let you down and offer a long service life.

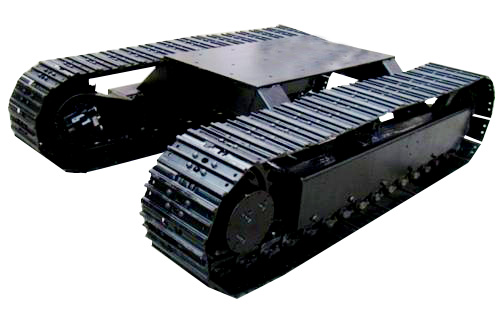

Tracked System

The basic element that enables the Scalper Screen to move is the tracked (crawler) system. Crawlers carry the entire weight of the crusher. FABO, which does not ignore the importance of the tracked system on the crushing plant, has carried out various R&D studies and has revealed the tracked system that provides maximum durability, low maintenance cost and long-term service to its user in accordance with A1 Quality CE standards.

Shipping Method

Tracked Scalper Screener is transported on the lowbed with the help of a tow truck. It is moved by remote control and positioned on the lowbed without the need for manpower.

Tracked Scalper Screen takes the shipping position within 5 minutes and saves time for our customers. Furthermore, it prevents superficial wear that may occur during transportation.