| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR |

|---|---|---|---|

| CRUSHER TYPE | Vertical Shaft Impact Crusher | CSS SETTING | 0-25 mm |

| ROTOR SIZE | Ø 900 | MAX.FEEDING | 50 mm |

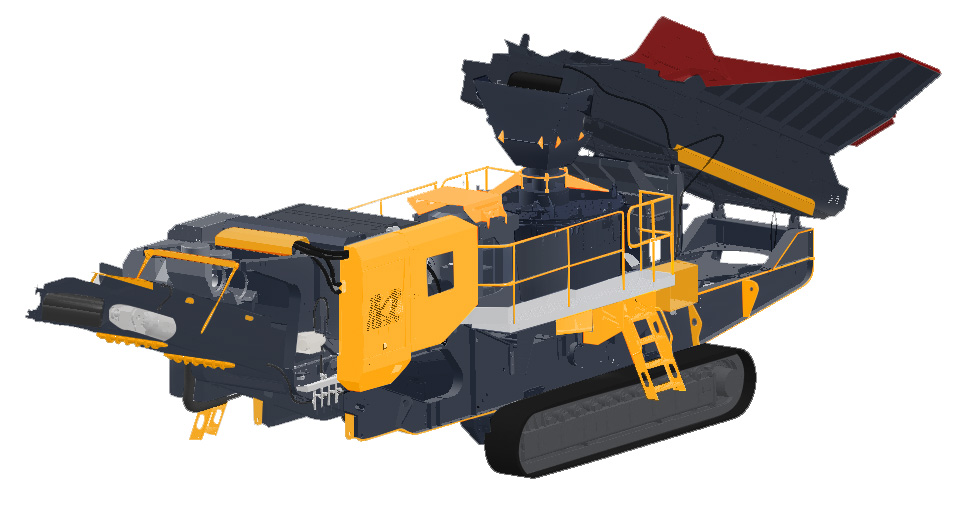

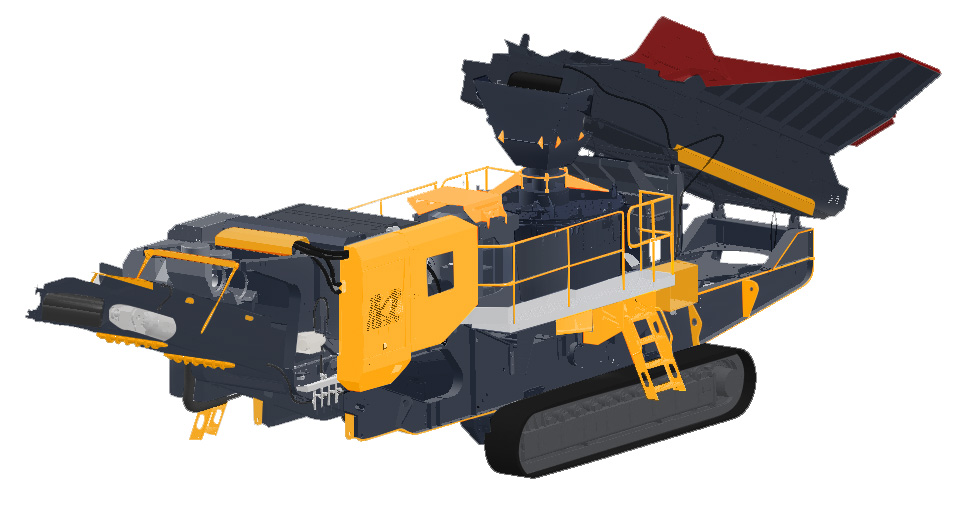

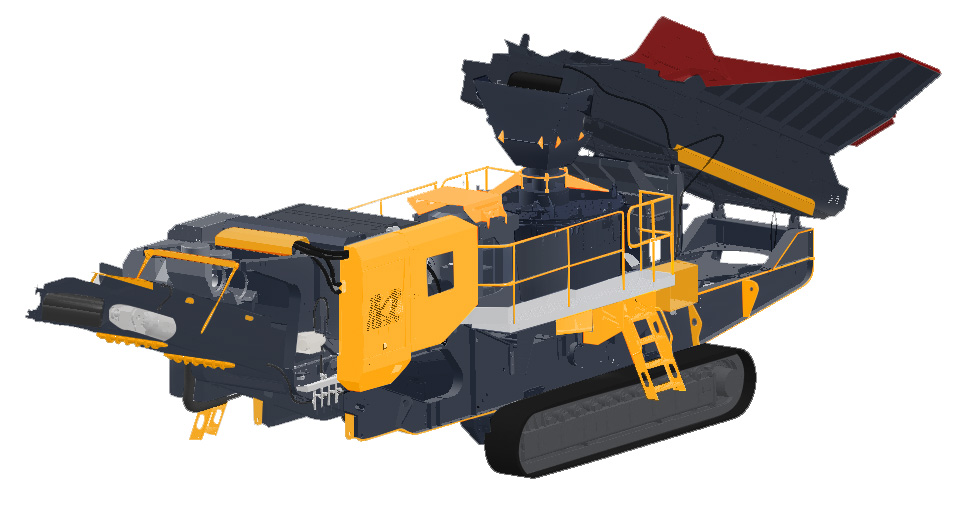

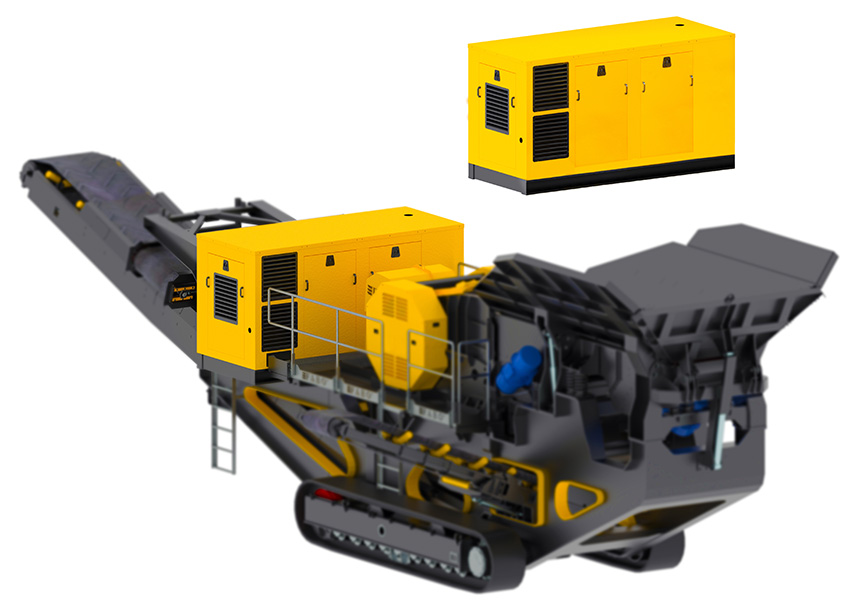

FTV-90 Tracked Vertical Shaft Impact Crusher

FTV-90 Tracked Vertical Shaft Impact Crusher; The feeding hopper is produced in the form of generator, vertical shaft impact crusher and with stock conveyor belts. FTV-90 Tracked Vertical Shaft Impact Crusher, which is moved with a remote control on a steel crawler, successfully completes all the commands given by the user by moving on its crawlers in all harsh climatic conditions and rough terrain.

Eliminates Infrastructure Requirement

FTV-90 Tracked Vertical Shaft Impact Crusher does not require an extra infrastructure as a production method, it is moved by remote control and adapts to all difficult terrain conditions.

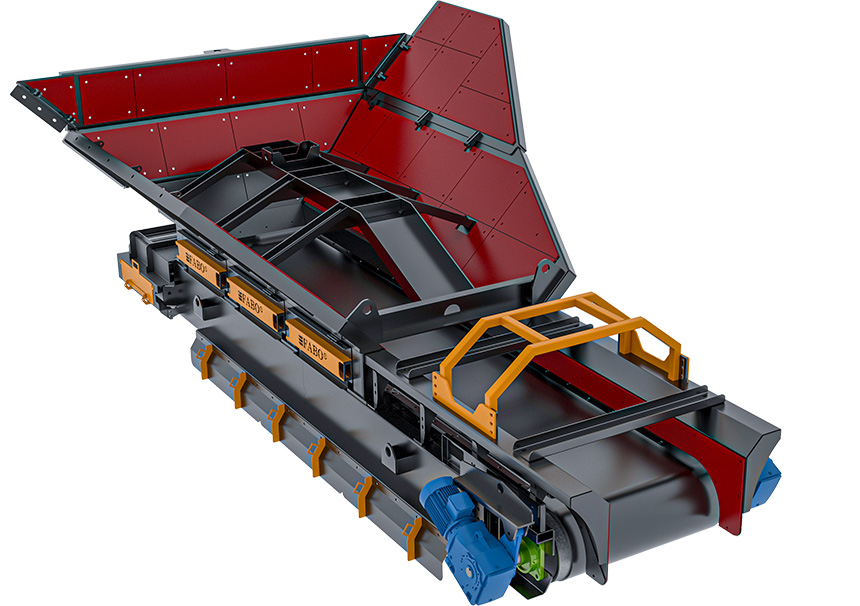

Belt Feeder

The Belt Feeder is the system in charge of quickly sending the loaded products to the crusher for the crushing process.

System has a motor protection system for 2 motors. Thanks to this system, malfunctions that may occur as a result of overheating are prevented.

The working intensity of the Belt Feeder and the crusher is coupled with the automation system.

This feature works in two steps.

Step 1: If the density of the crushed product in the crusher is high, the amperage of the crusher rises, this rise is detected by the automation system and the bunker transfer stops. It prevents product accumulation in the crusher feeding chute. This feature prevents the breaker from being worn out.

Step 2: If the density of the crushed product in the crusher is low, the amperage of the crusher decreases. This decrease is detected by the automation system and bunker transfer increases. The feeding hopper delivers the products to the crusher faster. This feature keeps the production capacity at the maximum level.

Vertical Shaft Impact Crusher

The vertical shaft crusher, which provides comfort during maintenance and cleaning thanks to its hydraulic feature, is effective in turning medium-sized materials of any hardness into sand or gravel. These crushers, which are used in a wide area, allow the materials to be crushed by hitting each other with high acceleration.

Basically, the working logic is as follows;

The feeding material is crushed by distorting the stone wall on the stator wall or the surrounding anvils.

With vertical shaft crushers, there is no need to use a screen. With special alloy rotor tips developed by our engineers, your work will never be interrupted and your maintenance costs will be reduced to a minimum.

You can call us for more detailed information about our products, which are produced in CE standards and environmentally friendly, and for vertical shaft crusher prices, and you can convey any of your problems to our support line.

Stock and Return Bands

With its foldable structure, it minimizes the dimensions of the machine it is on. Optionally, the number and length of tapes can be increased upon the request of the user.

10 mm EP 125 4-ply Band elastics, moving on 4mm st 37 Twisted Sheet, perfectly transport the aggregate coming out of the sieve to the area desired by the user in the most efficient way. The band tires, which are produced resistant to wear, will never let you down and offer a long service life.

Automatic Lubrication System (Optional)

The Automatic Lubrication System is the system in charge of sending the grease that is reduced during the use of the crushing plant and needs maintenance to the relevant part.

It distributes the grease evenly to all components of the mobile crusher that needs lubrication and provides perfect lubrication.

The automatic lubrication system, which provides great ease of maintenance, finishes the lubrication process in seconds without the need for manpower. It allows to use the Mobile Crusher Plant in the most efficient way.

It uses the amount of oil in the most ideal way during lubrication and minimizes the maintenance cost of the user.

Automation System

FTV-90 Tracked Vertical Shaft Impact Crusher is controlled by a full automation system. Thanks to the automation system panel on the machine, the working mode of the machine is adjusted. The working principle of the machine can be easily adjusted according to the shape of the material loaded by the user into the vibrating hopper.

The automation system, created by Fabo engineers, has been put at the disposal of its users in its most up-to-date form, taking into account all the tests performed from production to delivery.

It offers the opportunity to control the machine from anywhere in the world by using the remote connection feature with internet connection.

The automation system that allows you to use the Mobile Crushing and Screening Plant in the most efficient way has been prepared with PLC and serves its users with the most advanced state of technology.

Generator

The entire energy source of the FTV-90 Tracked Vertical Shaft Impact Crusher is provided by the generator. The generator power and the energy consumption of the crusher are calculated in harmony with each other and maximum energy time is provided in a single filling.

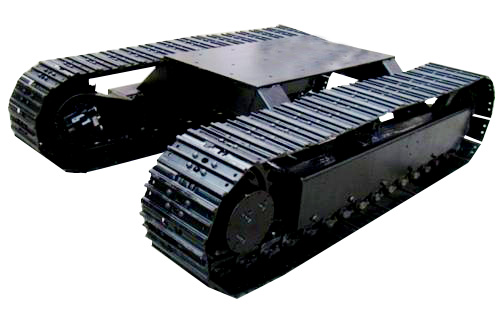

Crawler System

The basic element that enables the FTV-90 Tracked Vertical Shaft Impact Crusher to move is the crawler system. Crawlers carry the entire weight of the crusher. FABO, which does not ignore the importance of the crawler system on the crushing plant, has carried out various R&D studies and has revealed the crawler system that provides maximum durability, low maintenance cost and long years of service to its user in accordance with A1 Quality CE standards.

Shipping Method

FTV-90 Tracked Vertical Shaft Impact Crusher is transported on the lowbed with the help of a truck head. It is moved by remote control and positioned on the lowbed without the need for manpower on the crawlers.

FTV-90 Tracked Vertical Shaft Impact Crusher takes the transport position within 5 minutes, saves our customers time and prevents surface wear that may occur during transportation.