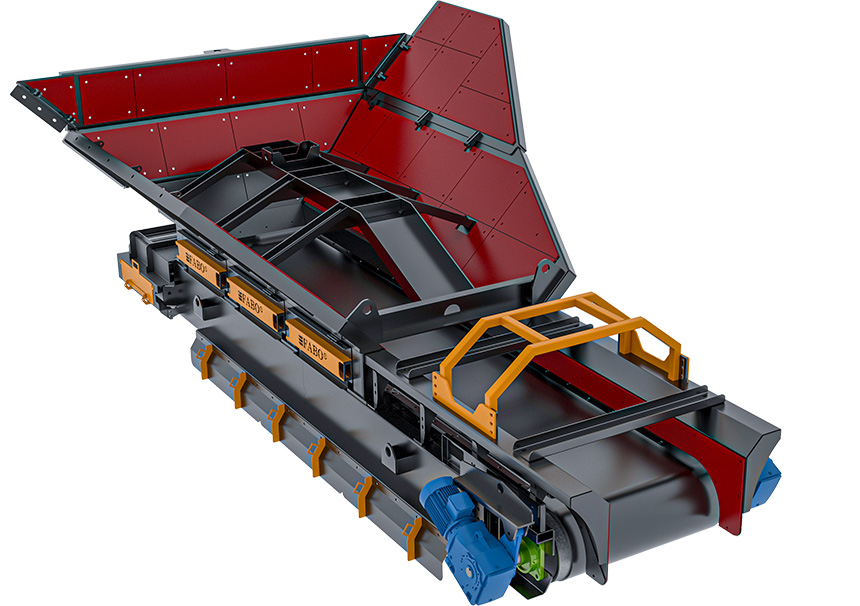

Belt Feeder

The Belt Feeder is the system in charge of quickly sending the loaded products to the crusher for the crushing process.

System has a motor protection system for 2 motors. Thanks to this system, malfunctions that may occur as a result of overheating are prevented.

The working intensity of the Belt Feeder and the crusher is coupled with the automation system.

This feature works in two steps.

Step 1: If the density of the crushed product in the crusher is high, the amperage of the crusher rises, this rise is detected by the automation system and the bunker transfer stops. It prevents product accumulation in the crusher feeding chute. This feature prevents the breaker from being worn out.

Step 2: If the density of the crushed product in the crusher is low, the amperage of the crusher decreases. This decrease is detected by the automation system and bunker transfer increases. The feeding hopper delivers the products to the crusher faster. This feature keeps the production capacity at the maximum level.