| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR |

|---|---|---|---|

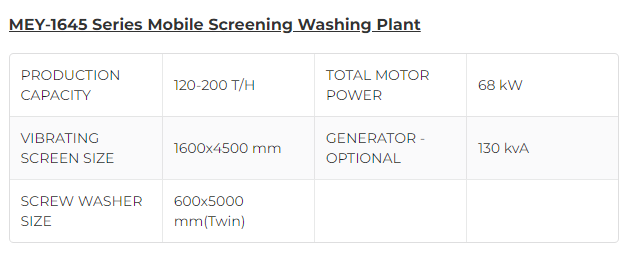

| PRODUCTION CAPACITY | 120-200 T/H | TOTAL MOTOR POWER | 68 kW |

| VIBRATING SCREEN SIZE | 1600x4500 mm | GENERATOR - OPTIONAL | 130 kvA |

| SCREW WASHER SIZE | 600x5000 mm(Twin) |

MEY-1645 Mobile Screening & Washing Plant

MEY-1645 Mobile Screening Washing Plant is produced on a single chassis in the most ideal way for screening and washing the material by using a grizzly feeder bunker, vibrating screen and screw washer.

MEY-1645 Mobile Screening Washing Plant, which performs screening and washing duties on a single chassis, is the most popular screening & washing plant with its minimum area coverage and high performance.

MEY-1645 Mobile Screening & Washing Plant washes and separates 4 different sizes of products with 4 different stock belts and 1 screw washer on its body and is the number one solution partner for our customers.

Grizzly Feeding Bunker

The Grizzly Feeding Bunker for MEY-1645 provides the sand to be loaded on the Mobile Screening & Washing Plant to be sent to the vibrating screen.

The grizzly system on the bunker prevents unwanted materials and large rocks from entering the bunker during feeding. The hydraulically opening and closing grid system is designed for you to use the MEY-1645 Mobile Screening Washing Plant in the safest way.

Grizzly Feeding Bunker with 7 m³ stock volume and with a vibration feature can be fed by Excavator, Loader and Truck.

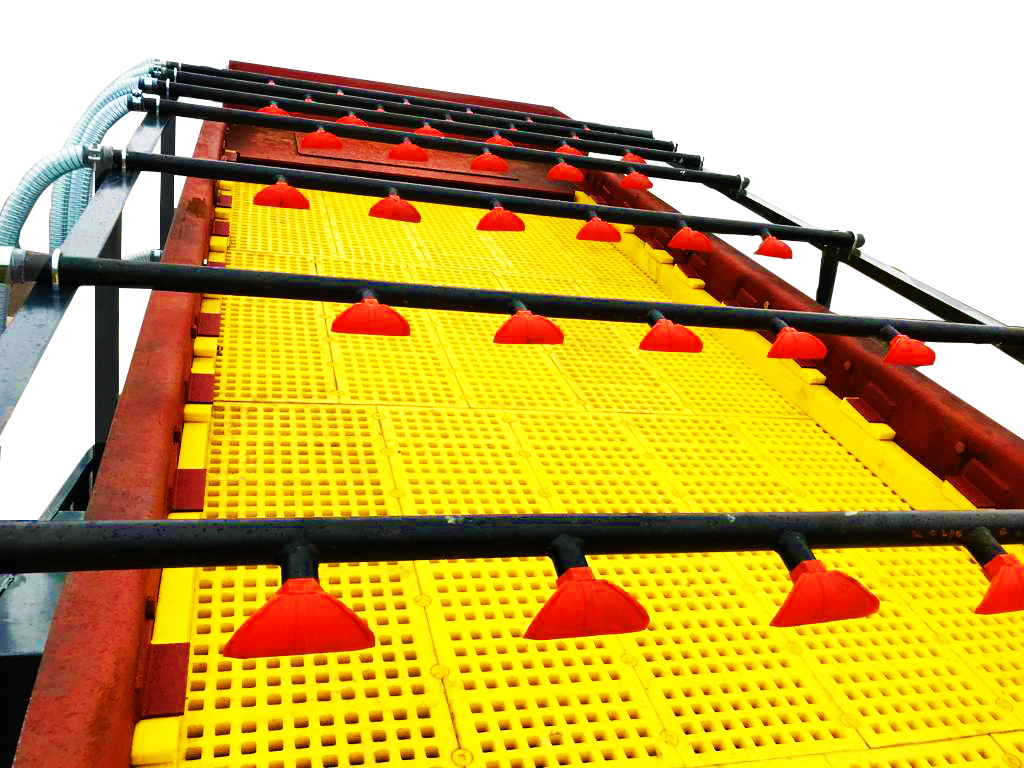

Vibrating Washing Screen:

The vibrating washing screen used after the vibrating bunker on the MEY-1645 Mobile Screening & Washing Plant sends the products over 0-5 mm to the washing and screening process and pours them to the stock area. The first step of the 2-step washing process starts here.

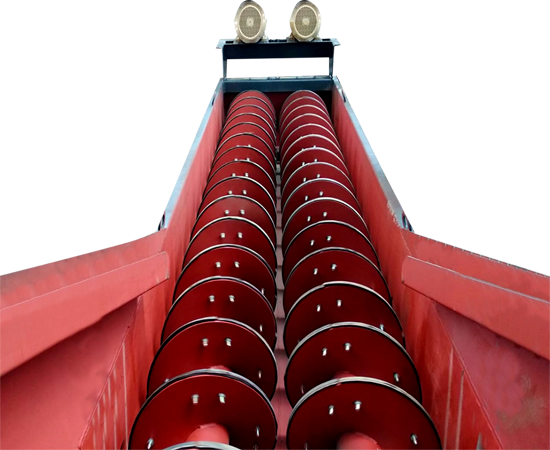

Screw Sand Washer (Spiral Sand Washer)

Screw Washer is the section where the sand that is received from the screening and washing process is carried from our MEY-1645 Model, is washed and dewatered and sent to the stock area with the help of the conveyor belts.

The 0-5 mm sand received through the vibrating screen is transferred to the screw washer. The products coming to the washing spiral begin to be washed by the rotation of 2 helix shafts moving in opposite directions. 2 units of helical shafts with 2×5,5 kW motor power provide optimum washing capacity.

Developed by Fabo Engineers as a user-oriented screw washer, after finishing the washing process of the products, it also performs the dewatering process of the product, thanks to the inclination of water flowing in the opposite direction. This feature ensures that the washed sand is stored dry and separated from each other. And it eliminates the need for the user to install an extra dewatering system

Stock and Return Bands

Fabo folding type feeding, feedback, stock conveyor belts are the vehicles that send the right product to the stock area according to the product’s recipe after separeting through the vibrating screen.

With its foldable structure, it minimizes the dimensions of the machine it is on. Optionally, the number and length of tapes can be increased upon the request of the user.

10 mm EP 125 4-ply Band elastics, moving on 4mm st 37 Twisted Sheet, perfectly transport the aggregate coming out of the sieve to the area desired by the user in the most efficient way. The band tires, which are produced resistant to wear, will never let you down and offer a long service life.

Automatic Lubrication System (Optional)

The Automatic Lubrication System is the system in charge of sending the grease that is reduced during the use of the washing and screening plant and needs maintenance to the relevant part.

It distributes the grease evenly to all components of the mobile crusher that needs lubrication and provides perfect lubrication.

The automatic lubrication system, which provides great ease of maintenance, finishes the lubrication process in seconds without the need for manpower. It allows to use the Mobile washing and screening Plant in the most efficient way.

It uses the amount of oil in the most ideal way during lubrication and minimizes the maintenance cost of the user.

Hydraulic System (Optional)

Hydraulics is the system that enables the parts on the washing and screening plants to move easily. Opening, closing and moving the machine’s carrying legs, feeding bands, bunker covers and washer feeder can be given as examples.

Hydraulic System Working Principle:

With the movement of the control arms, the hydraulic oil in can activate and the material to which the hydraulic system is connected the desired direction.

Automation System

MEY-1645 Mobile Screening Washing Plant is controlled by a full automation system. Thanks to the automation system panel on the machine, the working mode of the machine is adjusted.

The automation system, created by Fabo engineers, has been put at the disposal of its users in its most up-to-date form, taking into account all the tests performed from production to delivery.

It offers the opportunity to control the machine from anywhere in the world by using the remote connection feature with internet connection.

The automation system that allows you to use the Mobile washing and Screening Plant in the most efficient way has been prepared with PLC and serves its users with the most advanced state of technology.

Brake Axle System

The main factor that enables the MEY-1645 Mobile Screening Washing Plant to be moved easily is the axles at the rear. The load distribution of the plant is calculated by our engineers and the number of axles and their position are determined.

Shipping

Fabo MEY-1645 Mobile Screening Washing Plant minimizes the time and cash loss of the user with its ease of transportation. The MEY-1645 Mobile Screening Washing Plant developed by our engineers can be easily moved on a single chassis with a truck. MEY-1645 Mobile Screening Washing Plant, which is moved on axles, is ready for transportation in 10 minutes.

The MEY-1645 Mobile Screening Washing Plant, which we have created as a result of 18 years of knowledge and work, has been designed in the most ideal way for the user with its washing and screening capacity and easy transportation.

The brake system in the axle system has increased the life and property safety of the user to the highest level and has written its name in the sector with gold letters with 0% accident rate.

Fabo MEY-1645 Mobile Screening Washing Plant, which comes to the transport position without the need for manpower, is the leading washing and screening plant in the sector with the highest transportation speed.