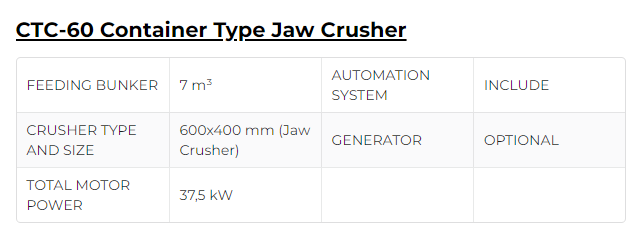

CTC-60 Container Type Jaw Crusher

| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR |

|---|---|---|---|

| FEEDING BUNKER | 7 m³ | AUTOMATION SYSTEM | INCLUDE |

| CRUSHER TYPE AND SIZE | 600x400 mm (Jaw Crusher) | GENERATOR | OPTIONAL |

| TOTAL MOTOR POWER | 37,5 kW |

| Turbomix-60 | TEKNİK DETAYLAR | Turbomix-60 | TEKNİK DETAYLAR |

|---|---|---|---|

| FEEDING BUNKER | 7 m³ | AUTOMATION SYSTEM | INCLUDE |

| CRUSHER TYPE AND SIZE | 600x400 mm (Jaw Crusher) | GENERATOR | OPTIONAL |

| TOTAL MOTOR POWER | 37,5 kW |

CTC-60 Container Type Mobile Jaw Crusher is produced on a single chassis including Feeding Bucker, Jaw Crusher, Bypass Conveyor Belt, and Stock Conveyor Belts.

Working Type:

1-The material loaded into the vibratory feeding bunker firstly removes the waste material with the help of the bypass conveyor belt and sent to the stock area without being subjected to the jaw crusher.

2-The material that passes the bypass stage is transferred to the jaw crusher and is crushed until the desired size is achieved by the user and sent to the stock area with the stock conveyor belts.

The feeding bunker, which serves its users with its 7m3 capacity, has been designed by Fabo Engineers to offer our customers many years of service life.

Specially produced steel springs that provide vibration of the bunker work in harmony with the automation system developed by Fabo and provide vibration at the frequency desired by the user.

Jaw Crushers are the starting point of production at the CTC-60 Mobile Hard Stone Crushing Plant. The material poured from the bunker gets crushed into the jaw crusher. Thanks to the hydraulically adjustable jaw opening, the size of the desired product can be changed. It has a robust structure and it serves the user for a long time.

It is possible to adjust the FABO jaw crushers with the hydraulic adjustment mechanism. This system allows the lower jaw opening to be adjusted easily and quickly according to the product you want to take from the machine.

With its foldable structure, it minimizes the dimensions of the machine it is on. Optionally, the number and length of tapes can be increased upon the request of the user.

10 mm EP 125 4-ply Band elastics, moving on 4mm st 37 Twisted Sheet, perfectly transport the aggregate coming out of the sieve to the area desired by the user in the most efficient way. The band tires, which are produced resistant to wear, will never let you down and offer a long service life.

The automation system, created by Fabo engineers, has been put at the disposal of its users in its most up-to-date form, taking into account all the tests performed from production to delivery.

It offers the opportunity to control the machine from anywhere in the world by using the remote connection feature with internet connection.

The automation system that allows you to use the Mobile Crushing and Screening Plant in the most efficient way has been prepared with PLC and serves its users with the most advanced state of technology.