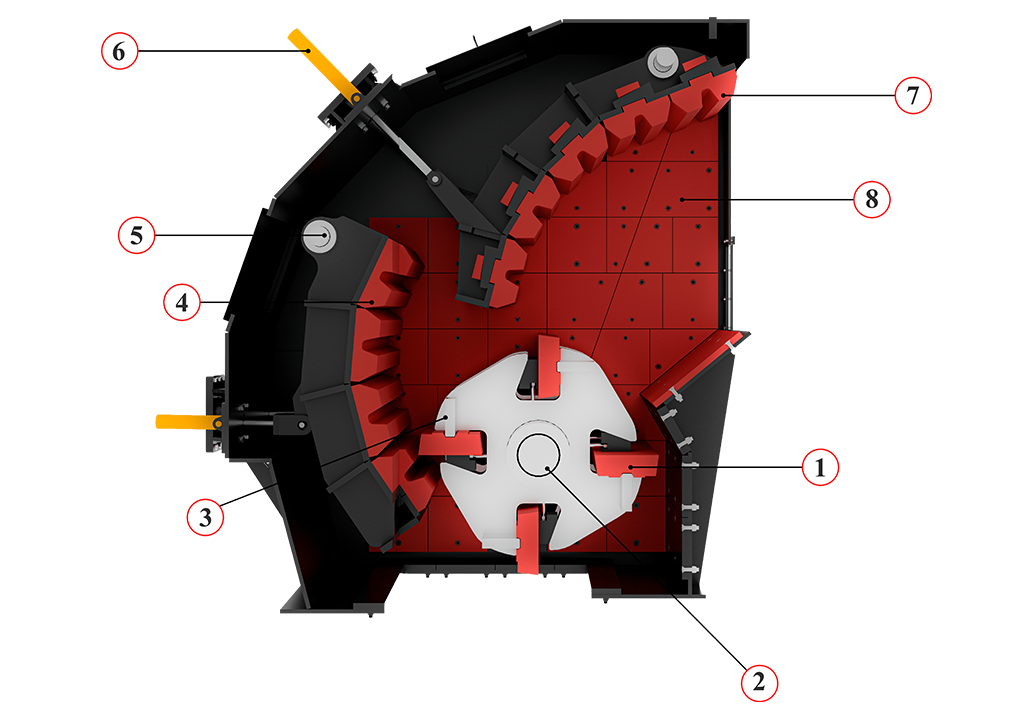

Tertiary crusher

Its body, which can be opened thanks to 2 hydraulic pistons, provides convenience for maintenance and spare part replacement.

The products falling into the Tertiary Crusher break the products by hitting the pendulum with the rotor arms rotating at high speed. This process continues until 0-5 mm of product is obtained. When the crushing process is finished, the discharge doors of the crusher are opened and the product is sent to the vibrating screen.

The main factor in product crushing is the rotor and crushing arms. FABO engineers, who did not ignore this important factor, carried out important studies for rotor robustness. FABO, which enables the rotor to work in both directions, provides bidirectional rotation of the rotor in the desired condition in order to minimize the wear on the pallets. Rotor rotation speed, the opening of the crushing pallets can be controlled by the automation system. The rotor, which is described as the heart of the Tertiary Crusher, reaches a speed of 750-1100 rpm. Thanks to its high speed capacity, it shreds the loaded product as soon as possible.

FABO Tertiary Crushers, which is the leader in 0-5 mm product production, is the solution partner of its users in production with 100% customer satisfaction.