Engineering marvel with compact design!

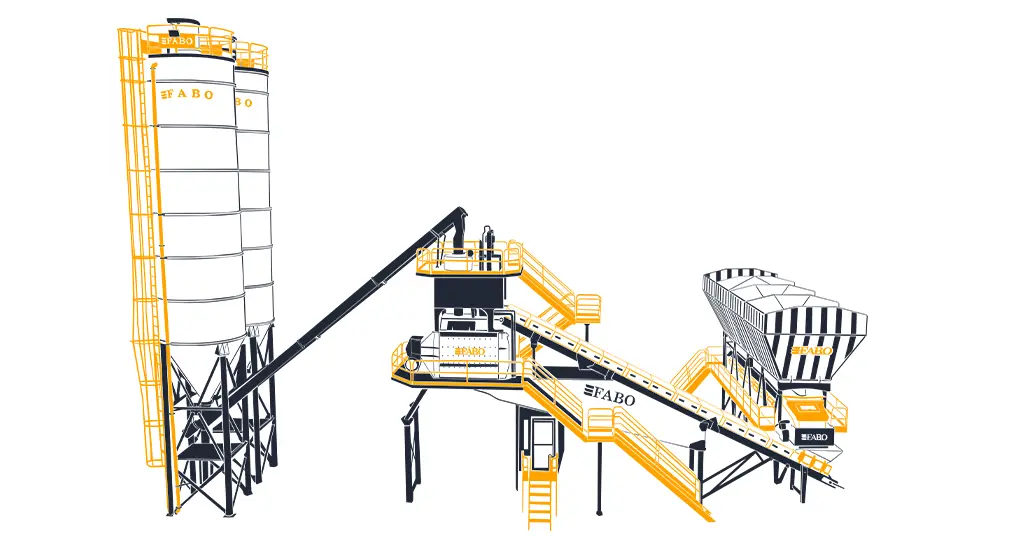

Compact Concrete Batching Plants have the ability to be installed in limited construction sites. With its compact design, it can be installed in the limited areas.

Compact Concrete Batching Plants for Easy Maintenance and Low Operating Costs.

Compact Concrete Batching Plant keeps operation and maintenance costs at the lowest level with its minimised structure and user-friendly design. The concrete batching plant is operated by one personnel and produces ready-mixed concrete without interruption.

One Button is Enough for Concrete Production in Accordance with the Prescription.

The most important factor for the smooth operation of concrete batching plants is the automation system. FABO engineers, who did not ignore this, implemented the Compact Concrete Batching Plant automation system using PLC technology. Compact Concrete Batching Plant produces all types of concrete in accordance with the concrete recipe.