Compact Concrete Plant

FABO Stationary Crushing Plants, which are the product of superior engineering studies and 21 years of experience, are just a click away.

Request an Offer Now!

FROM DESIGN TO REALITY

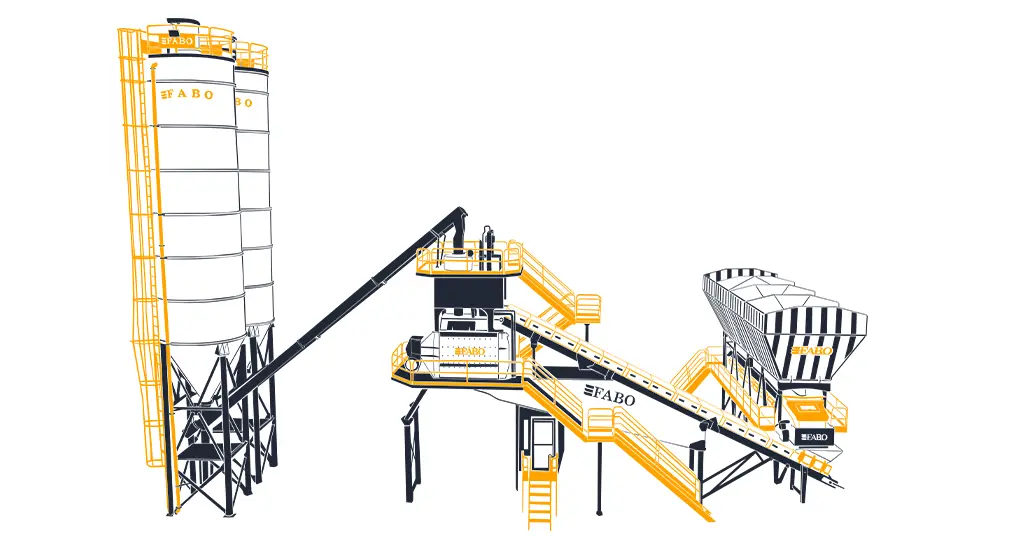

Concrete Production with Compact Concrete Batching Plant

Compact concrete batching plant is produced in two different models as bucket type and belt type.

The concrete batching plant, which is used in the narrowest construction site areas, meets all concrete production needs of our customers with its high production capacity. The compact concrete batching plant, which emerged with the combination of durable production material and advanced engineering, is the number one solution partner for ready-mixed concrete production for many years.

Accelerate Production with High Aggregate Storage

Compact Concrete Batching Plant has a high capacity aggregate bunker. Thanks to the high capacity aggregate bunker, the frequency of transporting the aggregate to the concrete batching plant decreases. Thus, fuel and energy savings occur and ready-mixed concrete production cost decreases.

What are Compact Concrete Batching Plant Equipment?

- Aggregate Bunker

- Aggregate Weighing Bunker

- Transfer Band

- Twin Shaft Mikse

- Cement Weighing Group

- Additive Weighing Grub

- Water Weighing Grub

- Cement Silos

- Automation System

- Compressor

- Control Cabin

Advantages of Compact Concrete Plant